Changing market requirements, individualized products with an enormous range of variants and increasingly shorter production cycles are presenting intralogistics with major challenges. Fixed handling and transport systems lack the necessary adaptability. Fully networked, automated production in line with the principles of Industry 4.0 requires integrated transport and process solutions with intelligent control, high energy efficiency, maximum flexibility and maximum availability.

Intelligent Process Linking

With the modular monorail system montrac®, the German manufacturer montratec GmbH offers new possibilities to handle complex internal transport tasks and assembly processes more intelligently, quickly and efficiently. The globally active company, headquartered in Dauchingen (Baden-Württemberg, Germany), has been part of the US-based Columbus McKinnon Corporation since 2023, but can draw on many years of expertise in the development and production of innovative intralogistics solutions. In 2024, the company was recognized for the third time in a row as one of the TOP 100 innovators among German SMEs in a scientifically based selection process.

The montrac® modular transfer system is based on a modular, flexibly expandable aluminum monorail system. Various types of transport shuttles with a maximum load capacity of up to 70 kg run on this system at speeds of up to 55 m/min with minimal impact. Autonomously driven and controlled, they independently find the optimal route to the transport destination, even over different transport levels and under the ceiling.

As a result, production processes can be linked between robots and workstations in a highly flexible manner, maximizing the automation of manufacturing processes regardless of the batch size. It is therefore no surprise that leading medical facilities and industrial companies in the automotive, plastics, consumer goods, optical, food, medical and pharmaceutical industries, among others, use montrac® to maximize material throughput and minimize cycle times.

Media Discontinuity Delays Implementation

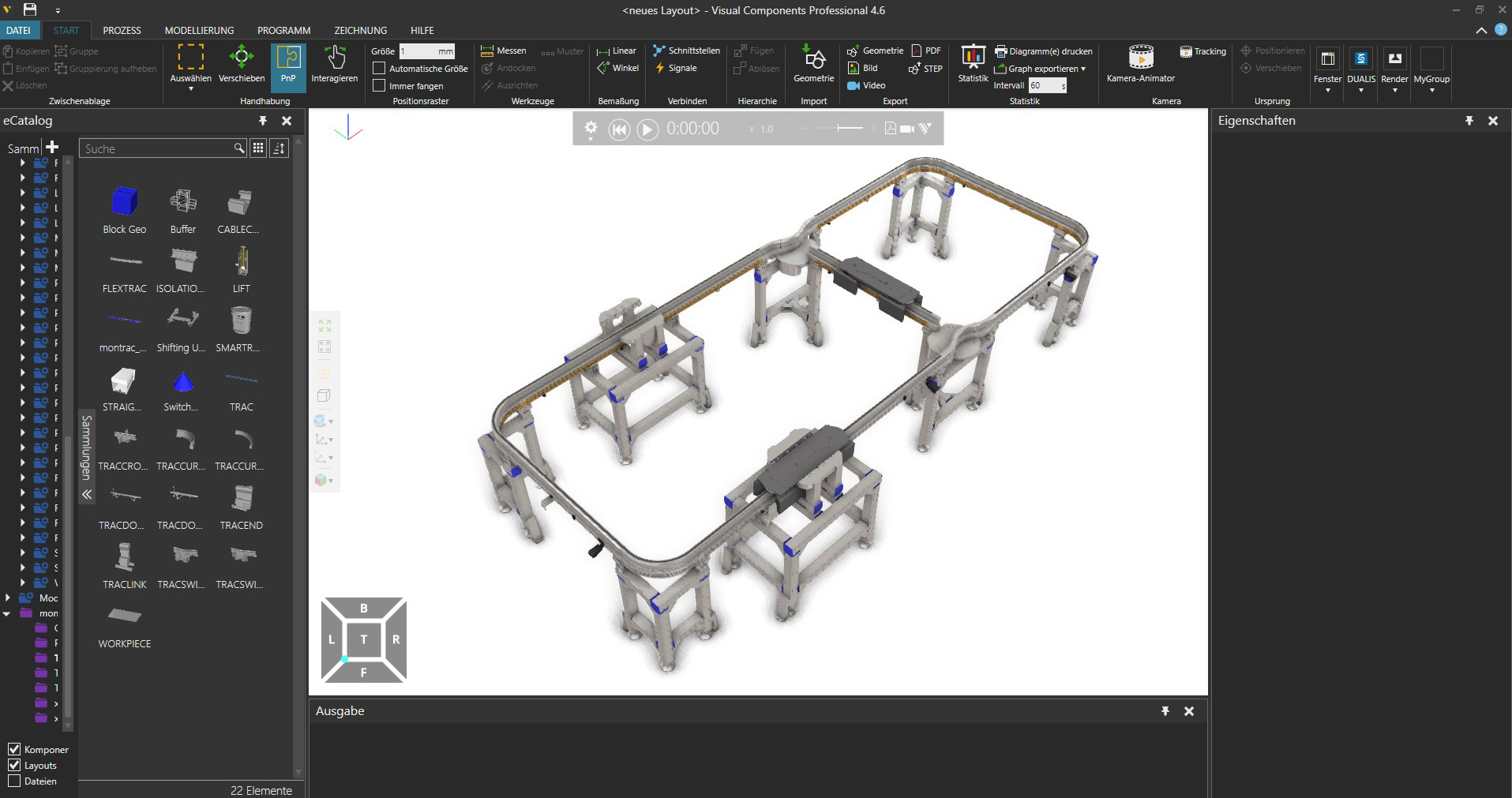

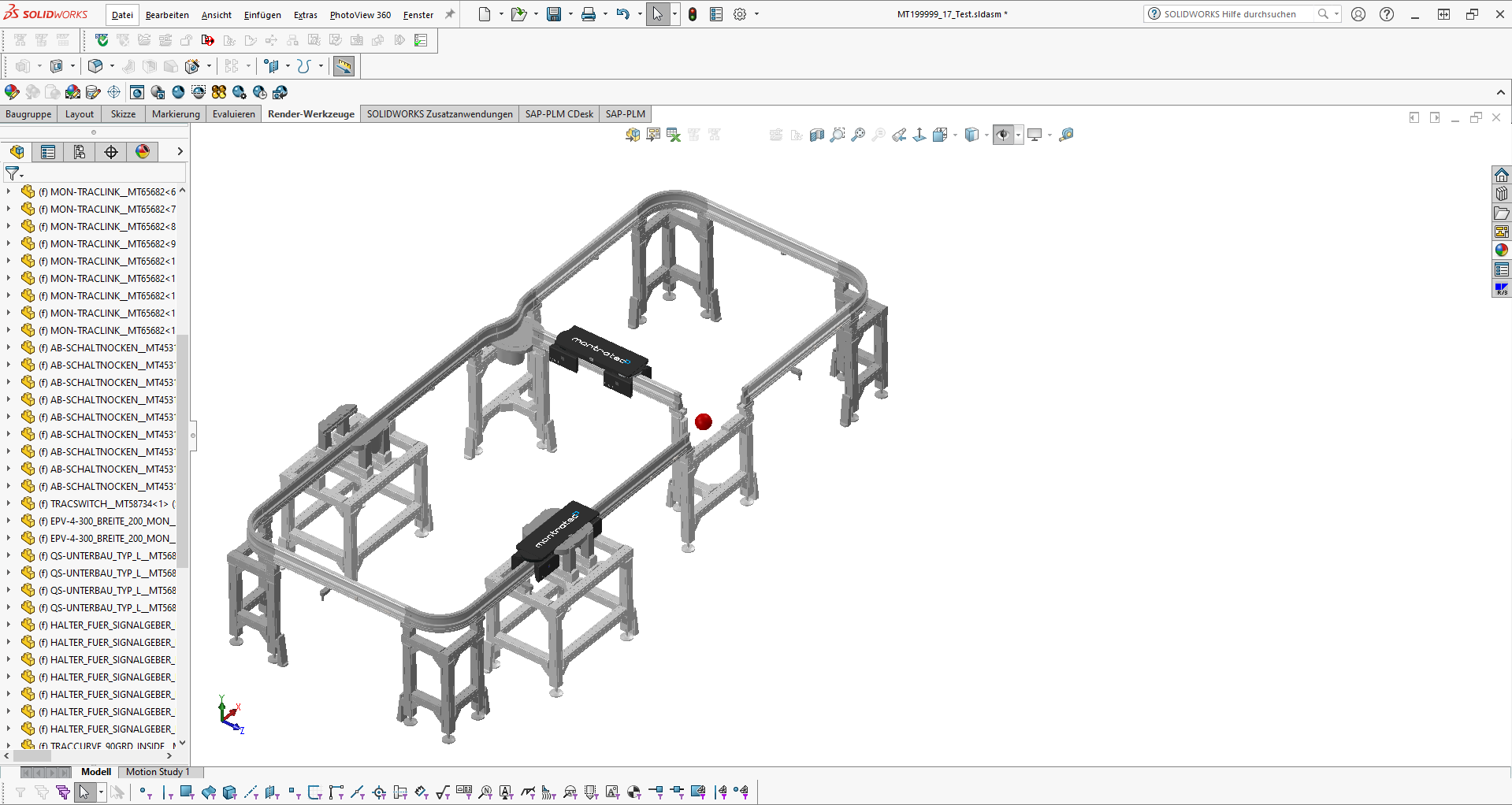

The flexible and compact transport system allows a task-specific, individual system layout with diverters, crossings, tight curves and lift elements for connecting workstations on several levels. This is created by montratec's specialist planners using the montrac® configurator. Based on commercially available system planning software, the montrac® configurator enables planning, visualization and simulation of the montrac® system design in 3D. External 3D data, for example from machines or building components, can be imported and taken into account.

Although this solution works to the satisfaction of everyone involved, until a few years ago it had a decisive disadvantage. “Since there was no connection to our PLM software, our engineers had to completely recreate the final configuration,” explains Matthias Magrian, Product Manager at montratec. “To save them from having to do this twice and to eliminate the associated sources of error, we wanted to eliminate this media discontinuity and automate the data transfer.”

Read more about the project between montratec and Cideon in the reference report:

How do you become a Cideon reference customer?

Are you currently working successfully with us on a joint project? Each of our customers is individual, has specific requirements and therefore very different solutions that are implemented. For us, every customer project is unique and should be valued just as much.

In our reference reports we focus on your company, the project highlights and your benefits.

Would you like to present your company and the joint project even more prominently? Then simply contact your responsible Cideon Account Manager and we will take care of all the further details for creating a reference report and publishing it on our website, blog and social media.