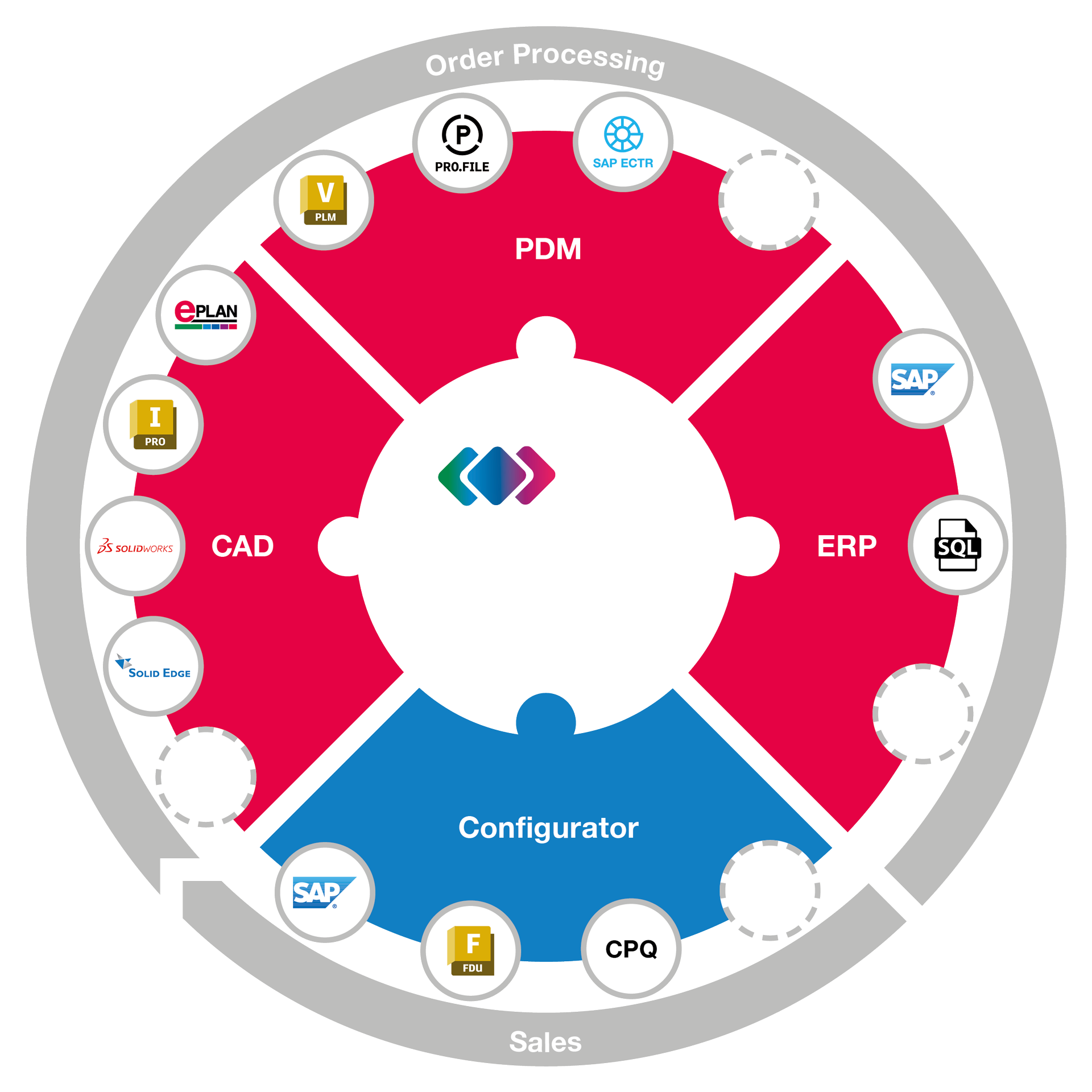

With Product Data Management (PDM), you can manage all relevant engineering and product data as well as related processes during the development of new or updating of existing products. This not only makes your planning and engineering stage faster, but also more efficient. PDM software offers a centralized solution for managing engineering and BOM data centrally. PDM systems guarantee professional change management, reliable document management and transparent versioning and revisioning at all times.

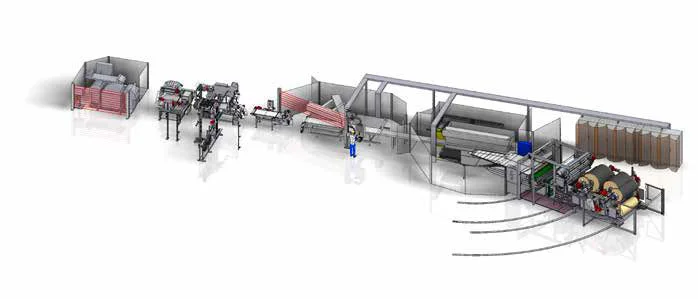

Product Lifecycle Management (PLM) extends well beyond the mere management of data and information generated directly during planning and engineering and aims to capture every single phase of the product lifecycle to make it more efficient. PLM incorporates all data and processes managed via PDM - such as production planning, manufacturing, sales, after-sales and fulfillment. In practice, there is no PLM without PDM. A PLM solution is based on a PDM system and therefore enables the efficient management and control of data and processes along the entire product life cycle. With PLM, you automate all processes in your value chain.