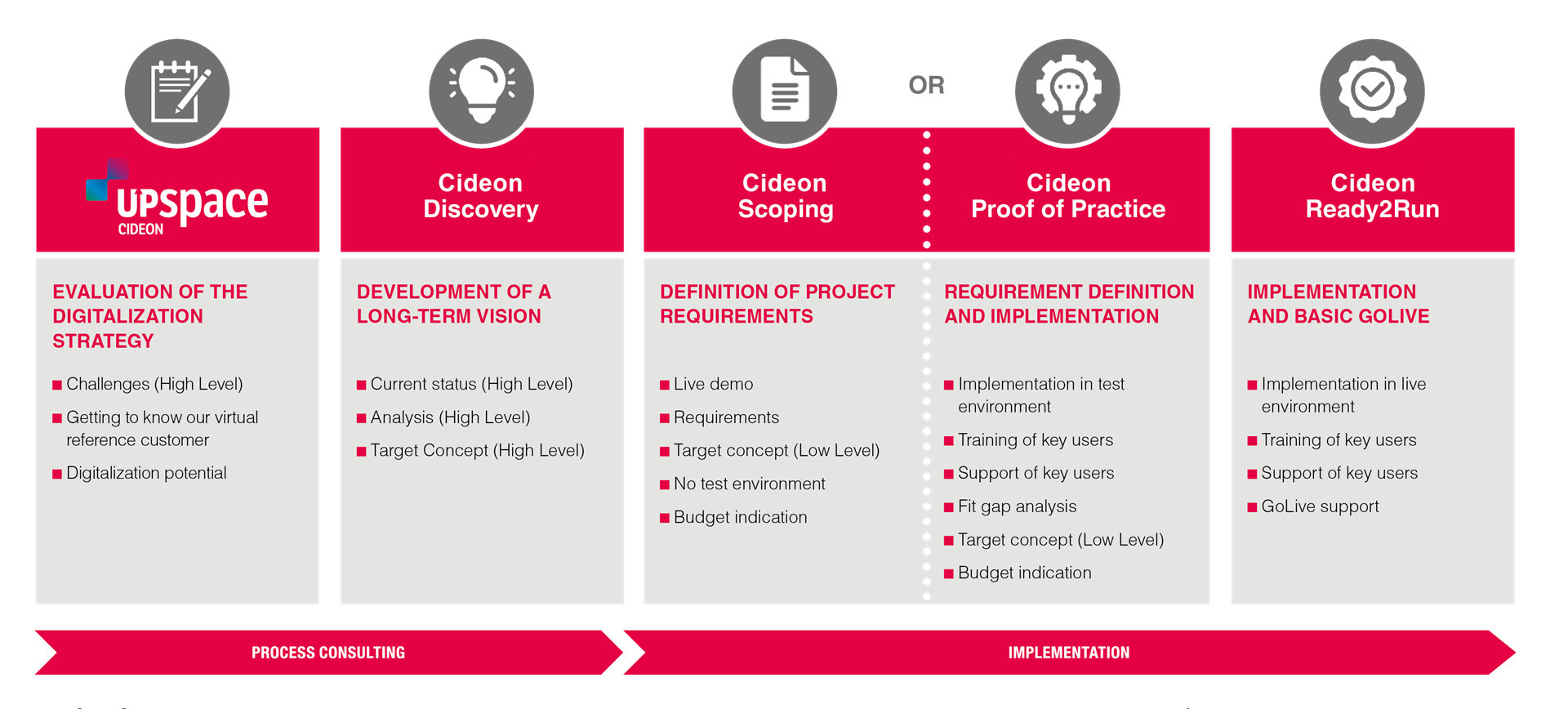

Process consulting:

Goal: Process consulting focuses on analyzing, evaluating and improving existing processes in the company. The aim is to establish more efficient processes and identify possible bottlenecks or inefficient working methods.

Procedure: This often involves conducting workshops, interviews and analyses to develop a comprehensive understanding of current processes. Recommendations for optimization are then made based on these findings.

Example: In terms of Cideon, this could mean analyzing a company's existing PDM/PLM processes to determine how they can be made more efficient. Recommendations could be made for the use of specific Cideon tools or adjustments to workflows.

Implementation:

Goal: Implementation focuses on putting the recommended improvements into practice. This may mean installing new software solutions, adapting or extending existing systems, and ensuring that the new processes are used effectively.

Procedure: This may involve installing and configuring Cideon software solutions, but also training staff to ensure they can use the new tools effectively.

Example: Following the process consultation, we could implement the recommended changes by deploying and configuring the necessary software components and ensuring that employees are trained to use the new workflows effectively.

To summarize: Process consulting focuses on analyzing and optimizing the existing workflows, while implementation aims to implement the suggested improvements, whether by deploying and configuring software or by training employees.