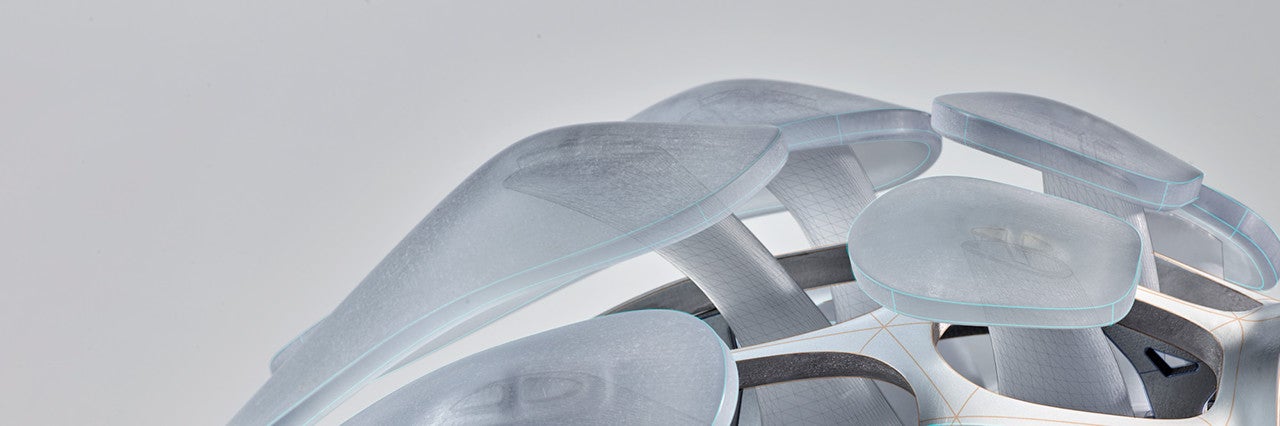

With Inventor Nesting, you can nest materials and sheet metal panels individually. Find out more about the other possibilities in sheet metal processing.

Efficient Nesting in CAD with Autodesk Inventor Nesting

Inventor Nesting is a software solution developed by Autodesk that specializes in the automated nesting of 2D and 2.5D parts for manufacturing. Nesting refers to the process of arranging 2D cut-outs, templates or parts on a flat sheet or sheet of material to minimize waste and use material efficiently. Autodesk Inventor Nesting is specifically designed for sheet metal fabrication and CNC machine optimization.

Nesting is integrated directly into Autodesk Inventor, making it possible to nest components associatively, as well as to calculate sheet metal components and assemblies more quickly.

Areas of Application for Inventor Nesting

Product Features of Inventor Nesting

Make the most of your sheet metal processing with Inventor Nesting and optimize the manufacturing process. Discover more benefits of the software:

Benefits of Autodesk Inventor Nesting

Inventor Nesting supports you in the planning, scrap reduction and NC data generation of your design. You don't have to step outside your CAD. Discover more benefits now:

Why Cideon?

Cideon advises and supports companies in optimizing their product development processes - from conception and engineering to production and service. We stand for:

Our Business Areas

Take advantage of our expertise and achieve more within your business area. Discover our industry-specific solutions and products at a glance.

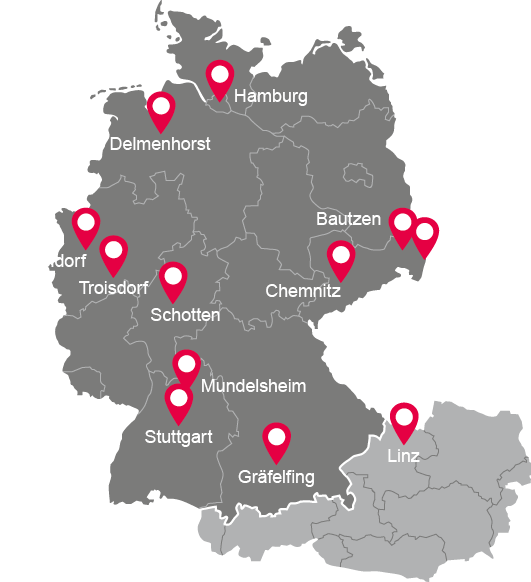

Cideon Locations

Cideon Headquarter

CIDEON Software & Services GmbH & Co. KG

Lochhamer Schlag 11, 82166 Gräfelfing (Germany)

Other Locations