Factory operators face a number of challenges when it comes to intelligent production monitoring. We present them briefly here.

Factory and production monitoring refers to the continuous monitoring and analysis of processes, buildings, machines and equipment in a production environment. The goal is to use modern technologies and systems to collect, visualize, and analyze real-time data from various sources.

We support you with our many years of experience in creating a factory and production model, integrating IoT and sensor data, and merging the data into a suitable system to enable holistic and seamless factory and production monitoring.

This includes integrating building technology, creating a database for forecasting, optimizing emissions, increasing energy and resource efficiency, and planning safety management.

The combination of these and other areas goes a long way toward maximizing efficiency, ensuring quality, minimizing downtime, and optimizing overall production performance.

Find out more about the challenges you face every day and how you can meet them with efficient plant and production monitoring. You can also discover our extensive range of consulting and services in the field of the 'digital factory'.

Factory operators face a number of challenges when it comes to intelligent production monitoring. We present them briefly here.

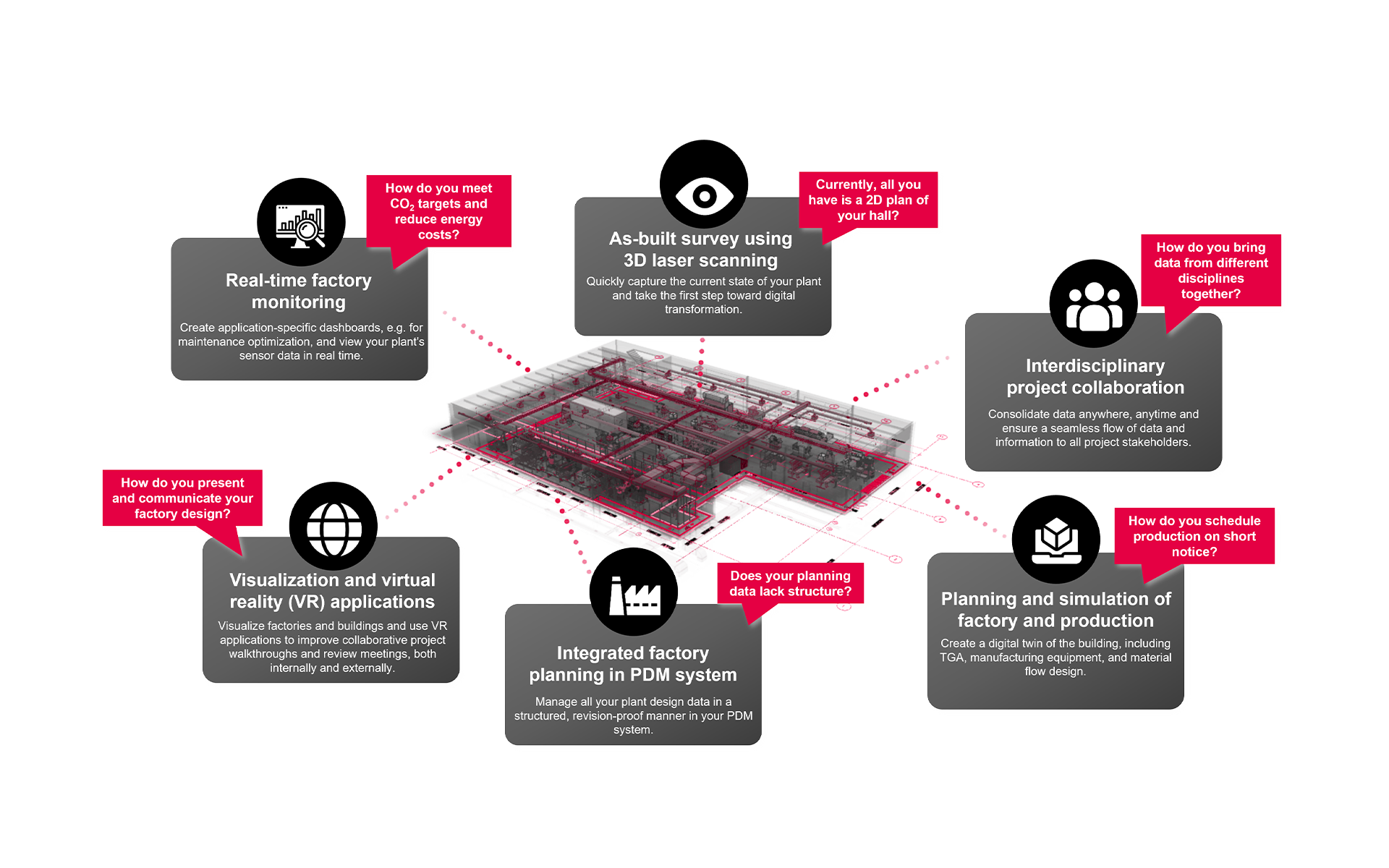

In order to effectively meet the current challenges facing factory operators and plant constructors, sustainable solutions for the digital factory are essential. In the following illustration, you can see what makes a factory a smart factory.

Setting up efficient factory and production monitoring has a variety of advantages. You can find some of them in the following list.

Discover efficient software for production monitoring and our Solution Discovery Workshop to identify potential in the area of the digital factory.

In day-to-day product development, engineering departments face a variety of challenges, from managing technological advances to ensuring quality and compliance. Cost pressures, global collaboration and the need for agile product cycles present additional hurdles.

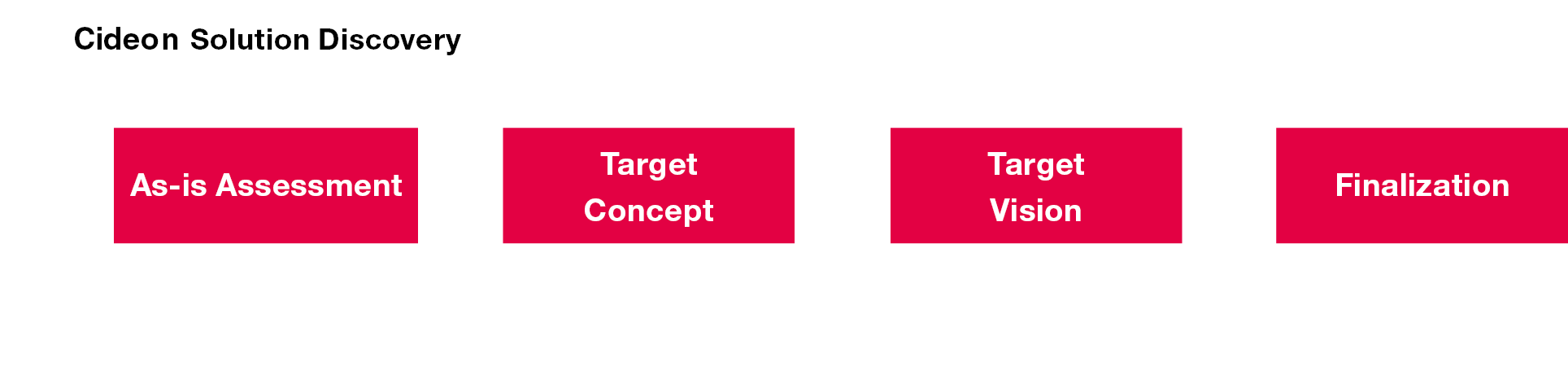

The Cideon Solution Discovery Workshop offers a proven method to make engineering processes transparent, identify potentials and address optimization and digitalization in this environment.

Factory operators face a number of challenges. In the area of factory and production monitoring, inadequate (real-time) data evaluation, manual analyses and missing emission values are major pain points. In addition, production processes and bottlenecks often cannot be tracked digitally.

Production monitoring is the monitoring and analysis of production processes in real time. The aim is to optimize performance, quality and efficiency and to detect malfunctions at an early stage.

Efficient factory and production monitoring improves the transparency, efficiency and quality of production processes and future decisions. The benefits of factory and production monitoring are faster error detection, reduced downtimes, optimized use of resources, increased productivity and a better basis for decision-making thanks to valid (real-time) data analysis. It also supports predictive maintenance.

Detailed production KPIs provide in-depth insights into your factory's key performance indicators (KPIs). They help to recognize trends, identify bottlenecks and optimize processes. Data-based forecasts allow decisions to be made more efficiently, risks to be minimized and long-term strategies to be improved.

Predictive maintenance is a strategy that uses sensors and data analysis to monitor the condition of machines and plants. The aim is to predict downtimes and only carry out maintenance when necessary. This increases efficiency, minimizes downtime and reduces maintenance costs.

Predictive maintenance minimizes unexpected failures, reduces downtimes and saves maintenance costs. It increases system reliability, extends machine lifespans and optimizes resources. Predictive planning increases efficiency and makes production more stable.

Cideon advises and supports companies in optimizing their product development processes - from conception and engineering to production and service. We stand for:

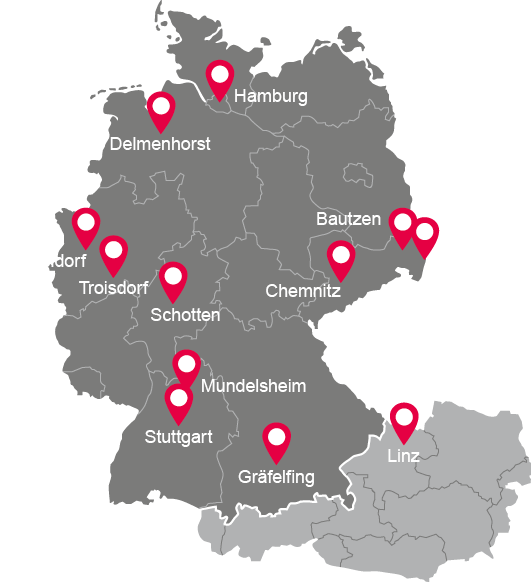

CIDEON Software & Services GmbH & Co. KG

Lochhamer Schlag 11, 82166 Gräfelfing (Germany)