Whether it's coping with rising material costs, the shortage of skilled specialists or complex supply chains – respond to the challenges in steel and metal construction with modern, digital solutions.

Modern metal construction is characterized by innovation, precision and versatility. It uses advanced technologies to produce complex structures efficiently. The focus is on sustainability and design flexibility, while digital planning tools optimize construction. With a wide range of materials such as steel, aluminum and stainless steel, modern metal construction can meet a variety of requirements and adapt to the challenges of an ever-changing world.

With software for metal construction, such as CAD programs, you are able to create solutions for these various challenges by optimizing planning and production, minimizing errors and increasing overall efficiency. Automation and integration into ERP systems further optimize processes. In this way, the requirements of modern metal construction can be met effectively.

Whether it's coping with rising material costs, the shortage of skilled specialists or complex supply chains – respond to the challenges in steel and metal construction with modern, digital solutions.

From product development to service, digitalized processes lead to innovative and customer-oriented solutions in metal construction. Whether it's the creation of 3D models, the programming of CNC machines or data interoperability – we will be happy to advise you and find the solution that suits your company.

Discover popular CAD, PDM and PLM software solutions for metal construction now.

Current challenges in metal construction include rising material costs, adapting to strict environmental regulations, a shortage of skilled employees, integrating new technologies such as 3D printing and ensuring supply chain stability. In addition, customer-specific requirements and faster production times call for innovative solutions.

CAD programs such as Autodesk AutoCAD and Autodesk Inventor are particularly suitable for metal construction. They offer specialized functions for the engineering of metal structures, including precise modeling tools, sheet metal processing functions and the ability to create complex assemblies. These programs help engineers and designers to efficiently create and visualize complex metal structures.

Manufacturing processes can be optimized through the use of software solutions such as ERP (Enterprise Resource Planning) systems. These enable efficient planning of resources, order management, inventory management and supply chain control.

In addition, CAD/CAM software and CNC programming offer precise control of production machines, which leads to higher productivity and quality. Digital communication platforms also improve collaboration between different departments and increase transparency throughout the entire production process.

CAM software solutions such as Autodesk Fusion are ideal for programming CNC machines in metal construction. Fusion offers a wide range of functions for CNC programming, including toolpath generation, tool libraries, simulation and postprocessors for various CNC machine types. It enables precise control and optimization of manufacturing processes in metal construction.

An ERP (Enterprise Resource Planning) system plays a key role in metal construction as it enables comprehensive management of resources, orders and processes. It optimizes the planning of materials and manpower, supports order processing and supply chain management as well as the tracking of production processes. By integrating financial and accounting functions, it provides a holistic view of business operations and helps to increase efficiency and profitability.

Metal construction 4.0 is driven by digital innovations such as AI (artificial intelligence) and automation. Smart factories use connected machines for autonomous work and real-time data analysis to optimize production processes. CAD/CAM software and 3D printing enable customized solutions. The digital connectivity of Industry 4.0 improves communication and efficiency along the entire value chain.

Quality assurance in metal construction is carried out through strict process control and testing procedures. This includes material testing, dimensional inspections and welding tests. State-of-the-art technologies such as digital testing and 3D scanning improve the accuracy and efficiency of quality assurance.

Software solutions support the entire product life cycle in metal construction by integrating planning, engineering, manufacturing, operation and maintenance. CAD/CAM software optimizes design and production, while ERP systems control resources, orders and supply chains. Processes in metal construction are continuously improved through digital integration and data analysis.

Cideon advises and supports companies in optimizing their product development processes - from conception and engineering to production and service. We stand for:

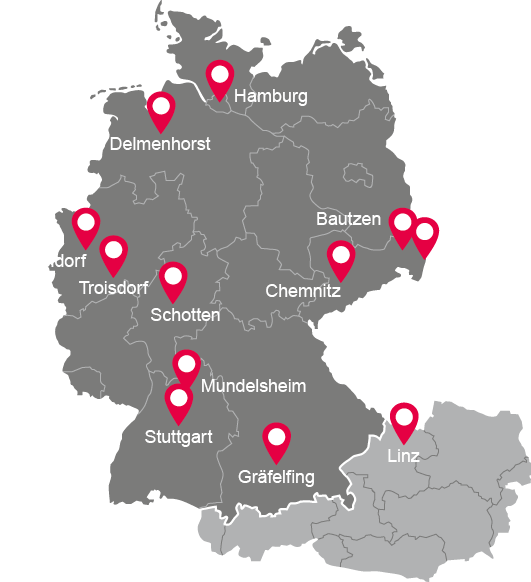

CIDEON Software & Services GmbH & Co. KG

Lochhamer Schlag 11, 82166 Gräfelfing (Germany)