There is a large number of departments that work with item lists and bill of materials to fulfill their tasks, such as cost estimation, work preparation or procurement. Do you know the challenges associated with this process?

Although the importance of the interdisciplinary mechatronic approach is undoubted, the daily work routine is often different. During product development, a bill of materials (BOM) is created in both MCAD and ECAD. These stand side by side, sometimes complementing each other, sometimes overlapping. There is no standardized data source that can be accessed by all persons and departments involved.

The challenge is to create an integrated mechatronic bill of materials that seamlessly combines the MCAD and ECAD data. Such an approach would improve communication and collaboration by creating a single source of truth for all stakeholders.

Integration increases efficiency, avoids redundant data and increases the accuracy of the bill of materials. A holistic view of the product during development is thus ensured, resulting in a smoother workflow and more effective product development.

There is a large number of departments that work with item lists and bill of materials to fulfill their tasks, such as cost estimation, work preparation or procurement. Do you know the challenges associated with this process?

The advantages for a mechatronic bill of materials are clear.

Our mechatronics & BOM workshops are standardized consulting methods for MCAD and ECAD. We help you to identify your potentials and to develop an overall solution to master your challenging mechatronic requirements.

The workshops focus on identifying your potential based on current and future desired working methods, the targeted development of an overall solution and its comprehensible presentation.

Data quality up, costs down - unite your MCAD and ECAD with a mechatronic bill of materials! Get to know our workshop packages in our video.

The mechatronic bill of materials is a BOM that combines mechanical and electrical parts and assemblies. It often also includes related areas such as hydraulics and pneumatics.

As information from the different systems and departments of a company is brought together and synchronized in a mechatronic bill of materials, sources of error are minimized. Processes are also accelerated and manual effort is eliminated.

The introduction of a mechatronic bill of materials requires several steps, which are different in every company. Basically, it involves standardizing data and processes and connecting systems.

How long the introduction will take cannot be said in general terms. It depends very much on which systems are used in your company, how the various departments interact with each other and what the specific project objective is. Mechatronics projects are always extensive, as entire processes and system landscapes are examined and optimized.

MCAD (Mechanical Computer-Aided Design) and ECAD (Electrical Computer-Aided Design) are software solutions used in product development. MCAD refers to the creation, analysis and optimization of mechanical systems, while ECAD is responsible for the planning and design of electrical circuits and systems.

Browse through our current webcast program for more exciting topics. Most of our past webcasts are available as recordings.

Software Solution for a Consistent Configuration Process

Cideon Conify consistently links data from the sales and engineering phases to automatically provide PDM-compliant MCAD and ECAD data of the configured product. This is the basis for the subsequent engineering-to-order and the creation of ERP-specific parts lists, work plans, circuit diagrams and production processes according to customer requirements, so that individual products can be created quickly and in accordance with specifications.

Main advantages:

Cideon Conify is the ideal combination of CONnection and CONfiguration!

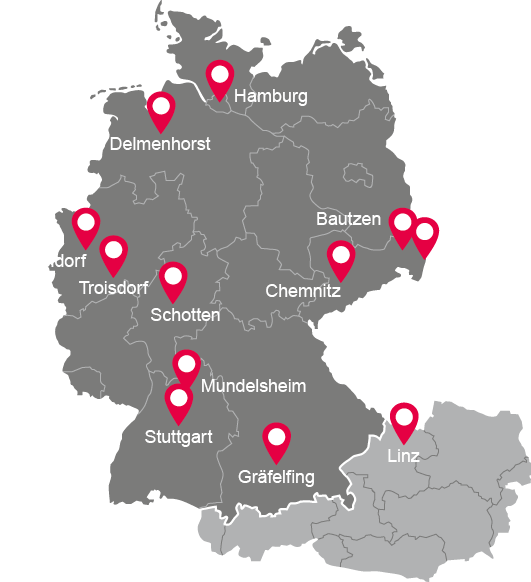

Cideon advises and supports companies in optimizing their product development processes - from conception and engineering to production and service. We stand for:

CIDEON Software & Services GmbH & Co. KG

Lochhamer Schlag 11, 82166 Gräfelfing (Germany)