The manufacturing industry is facing a variety of challenges, ranging from technological innovations to global market changes. We present some of them to you.

Manufacturing today deals with many topics simultaneously. They include Industry 4.0 with digitalization and automation, sustainability through resource-conserving production, agile manufacturing for flexible adjustments, quality assurance and, above all, efficient processes. Paperless production is also becoming increasingly important in the context of digital manufacturing.

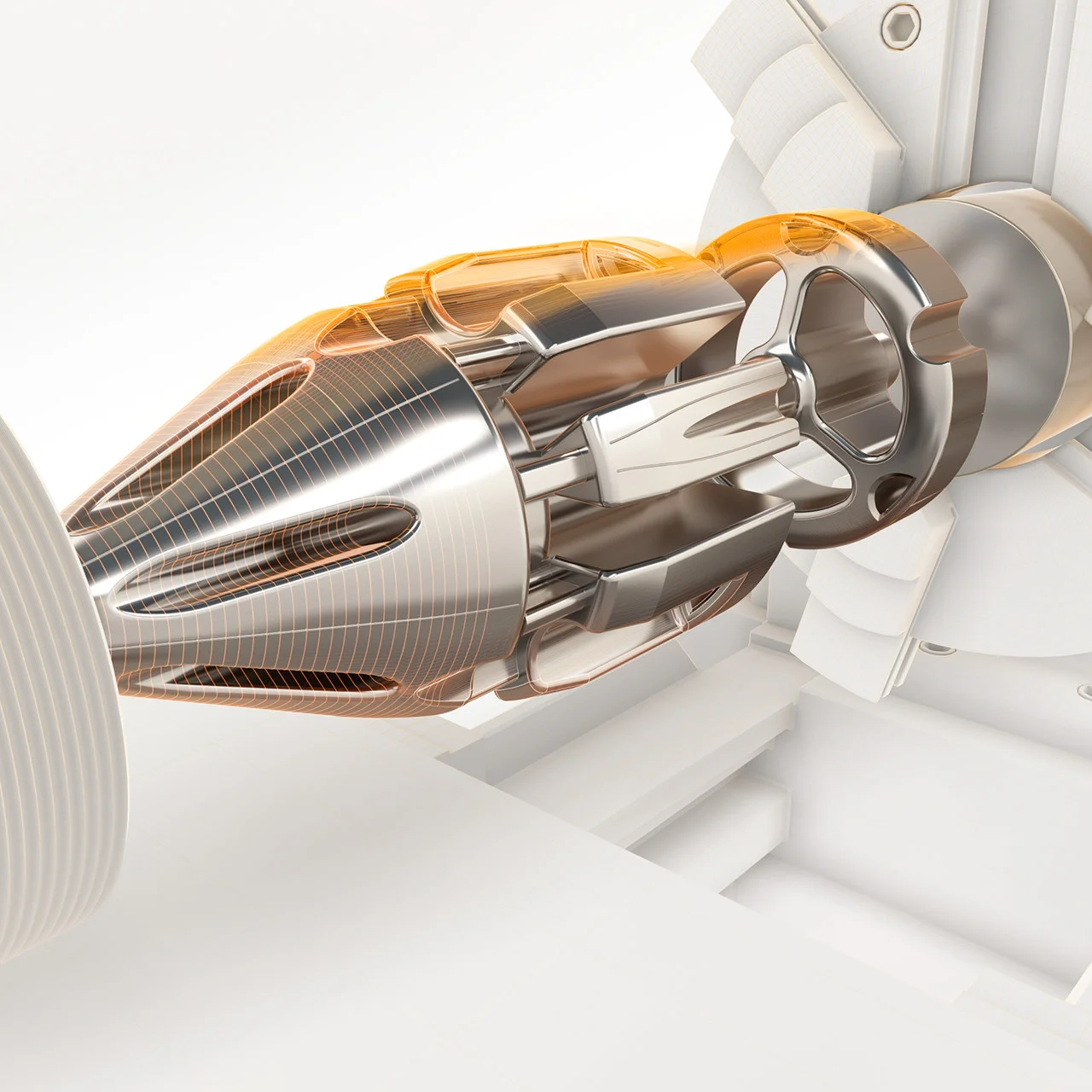

Cideon supports manufacturing companies with intelligent digital solutions to optimize manufacturing processes. You can rely on our decades of experience in CAD/CAM and PDM/PLM. We can help you with comprehensive process consulting, suitable software for manufacturing, training and support services, and much more.

The manufacturing industry is facing a variety of challenges, ranging from technological innovations to global market changes. We present some of them to you.

Digital solutions for manufacturing allow you to unlock greater potential for your tools and offer your customers better support for greater customer satisfaction. Discover digital manufacturing solutions now.

A major challenge in manufacturing is adapting to changing market requirements and customer needs. This requires flexibility in production and the ability to react quickly to trends and changes in demand. Technological innovations such as Industry 4.0 offer digital solutions, but require investment and retraining of the workforce. In addition, global supply chains and geopolitical uncertainties present risks that require flexible planning.

The selection of the right CAM software depends on the specific requirements of the manufacturing company, including the type of materials being machined, the complexity of the components, the desired functions and the budget. One of the leading software solutions is Autodesk Fusion, but other Autodesk CAM solutions are also suitable for various areas of computer-aided manufacturing.

The best software solutions for manufacturing are often those that enable seamless integration with existing systems and processes. Integrated functions for production planning, material management, quality control and more are important. A thorough analysis of the existing infrastructure and requirements is crucial in order to choose the best integration solution. We are happy to support you in this, for example by providing process consulting.

Yes, an ERP (Enterprise Resource Planning) system is extremely important in the manufacturing industry. It provides an integrated platform to manage various business aspects such as materials management, production, sales, finance and human resources. ERP software enables efficient resource planning, improved process control, better inventory management and a holistic view of the entire manufacturing operations. It also simplifies communication and collaboration between different departments and promotes decision-making through real-time data and reports.

We offer a comprehensive range of software training courses. From open training courses with fixed dates to company training courses and customized training courses, we have everything you need.

Industry 4.0 plays a crucial role in manufacturing by enabling comprehensive digitalization and integration of production processes. By using technologies such as automation, factories are becoming smarter and more efficient. This enables improved monitoring and control of machinery and equipment in real time, optimization of production processes, prediction of maintenance needs and adaptation to changing market conditions. Industry 4.0 also contributes to the creation of smart factories, in which more flexible and individualized production is possible and innovations can be driven forward.

Yes, saving energy is certainly possible in manufacturing and is playing an increasingly important role. By using energy-efficient technologies, optimizing production processes, implementing energy recovery systems and monitoring energy consumption, companies can significantly save money while reducing their environmental impact.

The issue of sustainability in manufacturing is also of great importance. Companies are increasingly striving for sustainable production practices in order to minimize environmental impact, use resources more efficiently and reduce their ecological footprint.

Cideon advises and supports companies in optimizing their product development processes - from conception and engineering to production and service. We stand for:

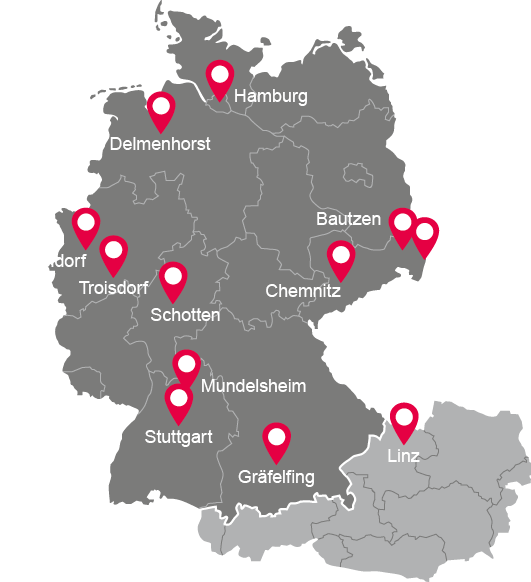

CIDEON Software & Services GmbH & Co. KG

Lochhamer Schlag 11, 82166 Gräfelfing (Germany)