There are a number of challenges that need to be overcome in machine building: from the advancement of digitalization to the shortage of skilled workers and the need for sustainable production.

Machine building companies are currently facing various challenges. These include the advancement of digitalization, a shortage of skilled workers and demands for sustainable production. Technological developments need to be used optimally in order to remain competitive and at the same time assume ecological and social responsibility.

This includes smart solutions in the areas of PDM, PLM and CAD. Machine building companies should also ensure efficient interaction with the ERP system.

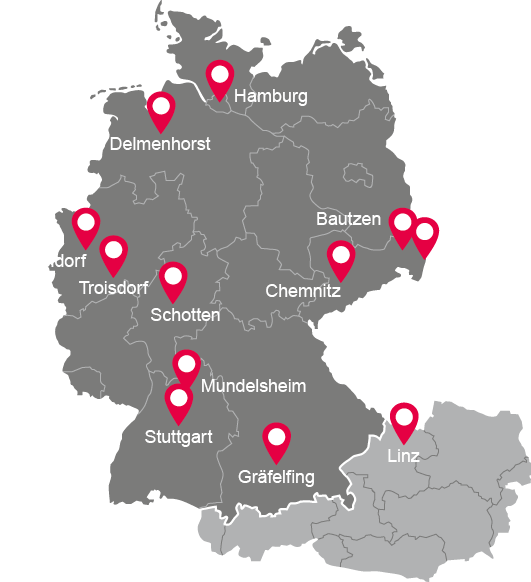

However, as a machine builder, you do not have to overcome these challenges alone: We are happy to help you with our many years of expertise in the areas of CAD, PDM and PLM as well as in individual software development. Whether it's process consulting, interfaces between key systems or training and support - the Cideon experts are here for you.

There are a number of challenges that need to be overcome in machine building: from the advancement of digitalization to the shortage of skilled workers and the need for sustainable production.

Digitalization offers a wide range of solutions for machine building that increase efficiency along the entire value chain. Discover the most important solutions for the industry now.

Discover popular CAD, PDM and PLM software solutions for machine building now.

The challenges in machine building reflect the dynamic development of the industry. A key issue is the advancing digitalization, which brings new opportunities, but digitalization projects can also lead to challenges, especially in the initial phase.

Another aspect is the constant need to bring innovative products faster to market, which puts pressure on development and production cycles. At the same time, companies must respond to global challenges such as sustainability and resource efficiency.

Demographic change and the shortage of qualified staff in machine building present additional obstacles. Long-term competitiveness can only be ensured with sufficient well-trained staff.

The future success of machine building and the opportunity to shape innovative solutions for the industry of tomorrow lie in dealing with these challenges.

Digitalization in machine building opens up various advantages to boost the efficiency and competitiveness of the industry. One key benefit is the increase in productivity through the automation of processes. This enables faster production on the one hand and more precise manufacturing on the other, which ultimately improves product quality.

More efficient use of resources can reduce costs, while at the same time increasing the possibility of implementing sustainable practices.

Digitalization offers great advantages when it comes to efficient (global) cooperation between project teams. Internal and external participants have access to important data at all times and can exchange information more effectively, which improves collaboration.

Overall, digitalization in machine building is helping to future-proof the industry by offering flexibility, agility and a clear competitive advantage.

Digitalization in machine building enables companies to increase their efficiency and product quality. Automation optimizes production processes and improves collaboration. This creates competitive advantages on the one hand and new opportunities to respond flexibly to market requirements on the other.

Various technologies are essential for digitalization in machine building. These include:

The effective combination of these solutions increases efficiency within the company, promotes collaboration and reduces product development costs.

Digitalization is revolutionizing the work environment in machine building. Automation is leading to more efficient production processes, while virtual collaboration and mobile technologies are enabling flexible ways of working. The digital transformation requires continuous adaptation and training, but it also creates more diverse and challenging work opportunities in machine building.

Small and medium-sized companies in the machine building industry can approach digitalization through step-by-step integration, starting with goals and a demand-oriented and scalable technology selection. Investing in training is crucial to prepare employees for working with new software solutions. Working with external experts, such as Cideon, can make it easier for SMEs to get started with digitalization and unleash innovative potential.

Effective project management in machine building is characterized by precise planning, clear objectives and transparent communication. It requires the integration of technologies such as PLM and ERP for optimal use of resources.

Continuous monitoring of project progress, adaptability to change and targeted risk management are crucial. Teamwork, clearly defined responsibilities and continuous reporting contribute to the successful implementation of machine building projects.

An ERP system in machine building is very important for coordinating complex processes. It integrates all departments, from procurement to production, into one central platform. This enables the provision of real-time data, improved transparency and efficient use of resources.

Precise control of production processes, optimization of warehouse management and adaptability to customer-specific requirements are only a few reasons why an ERP system is essential in machine building to boost competitiveness and innovative strength.

Cideon advises and supports companies in optimizing their product development processes - from conception and engineering to production and service. We stand for:

CIDEON Software & Services GmbH & Co. KG

Lochhamer Schlag 11, 82166 Gräfelfing (Germany)