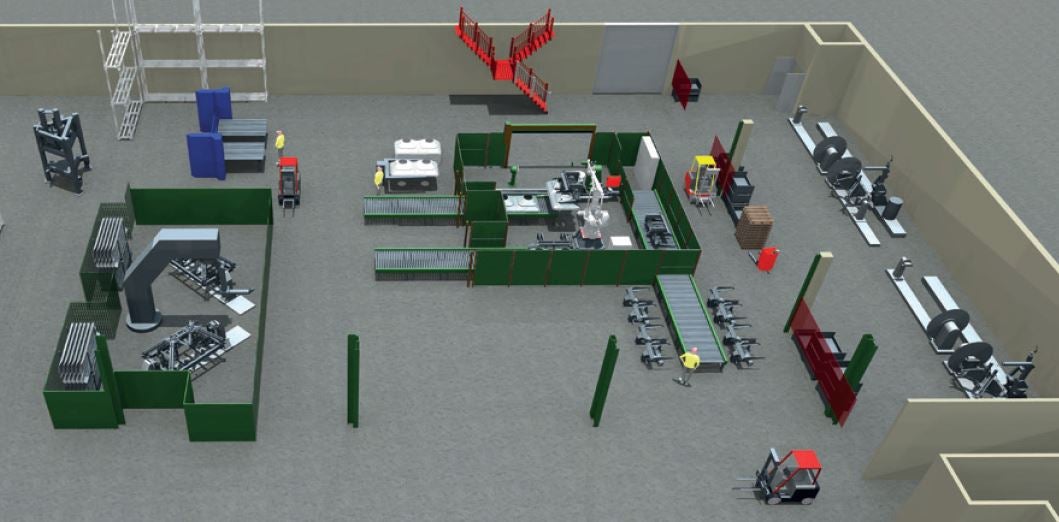

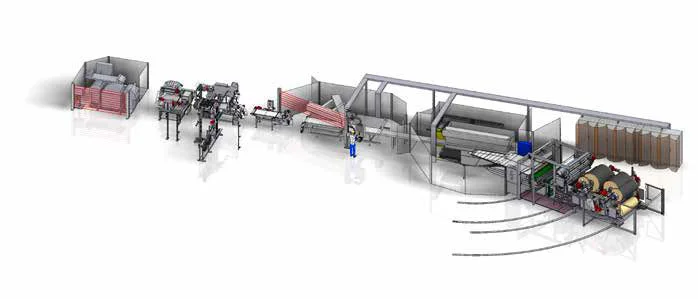

In the field of factory and layout planning, 3D laser scanning plays a decisive role by offering modern technologies for the precise assessment and documentation of existing plants and buildings, including building technology. State-of-the-art laser scanners are used to record millions of points per second and generate highly accurate 3D models of the as-built situation.

This data can then be transferred to planning software in order to use it as a basis for planning or to create CAD models from it. In contrast to traditional 2D plans, these models enable a detailed visualization and analysis of the given spatial conditions, including the exact dimensions, structures and surface textures.

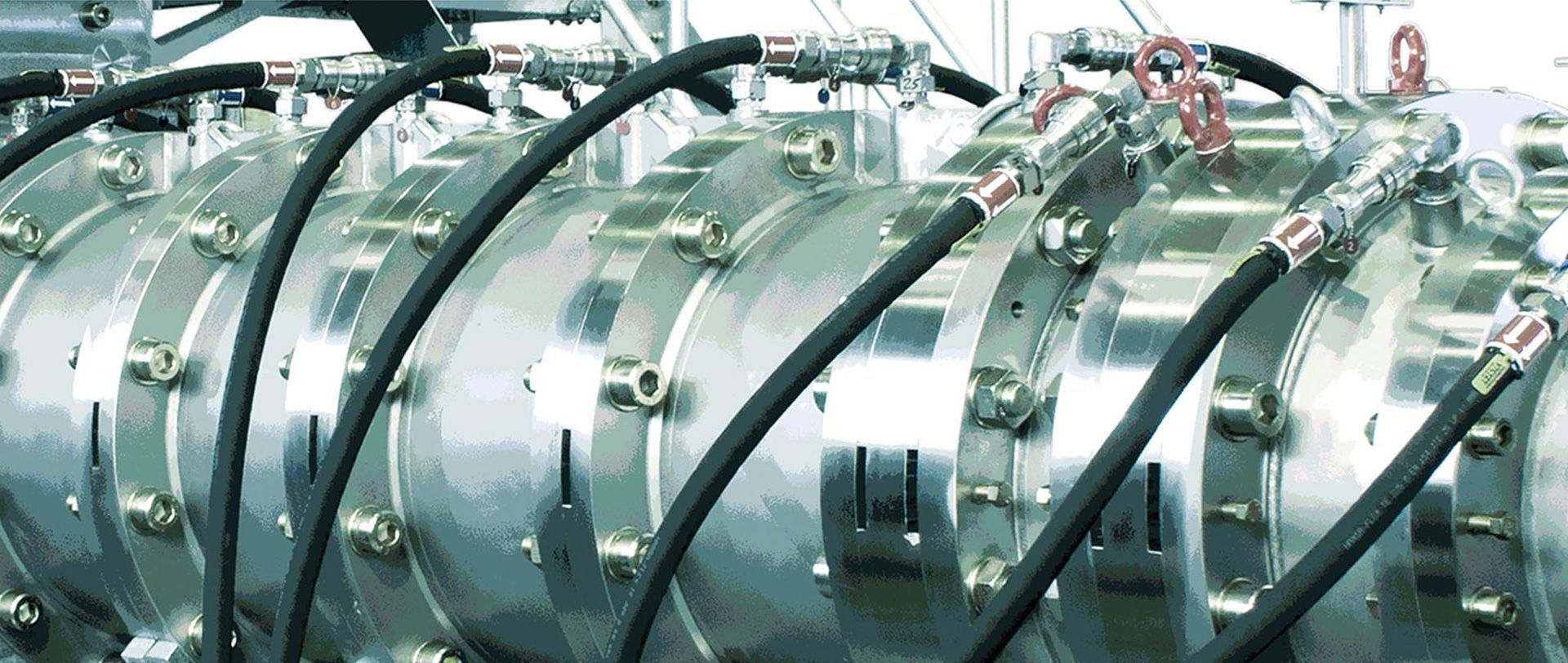

3D laser scans provide a reliable basis for planning and optimizing production facilities. By precisely capturing existing infrastructures, potential bottlenecks and optimization opportunities can be identified at an early stage. This leads to more efficient production processes and an improved utilization of space and resources. In addition, the scanning of areas that are difficult to access makes it easier to accurately record details that might be overlooked during manual capturing.

For plant operators, the use of 3D laser scanning offers numerous advantages. A precise data basis reduces planning errors and minimizes risks during the construction phase. This not only saves valuable time but also costs in the long term. Overall, the use of laser scanning contributes significantly to the competitiveness and sustainability of factories.

Do you also want to generate current 3D models of your factory building or plant so that you can work with an ideal planning basis? Contact us today for an initial non-binding consultation!