Engineer-to-Order (ETO) describes an order fulfillment process in which a product or component has to be developed, engineered and manufactured from scratch for the first time. This approach differs from the Configure-to-Order (CTO) process. In this case, the product is configured using firmly defined parameters and subsequently manufactured. Product development therefore takes place in advance.

ETO projects are usually highly complex and require close collaboration between customers, engineers, project managers and other stakeholders. As the products are customized, they can be more expensive and require longer development and production times than standardized products. However, ETO enables customers to tailor products to their exact needs, which can be a great advantage in industries with special requirements and customized solutions.

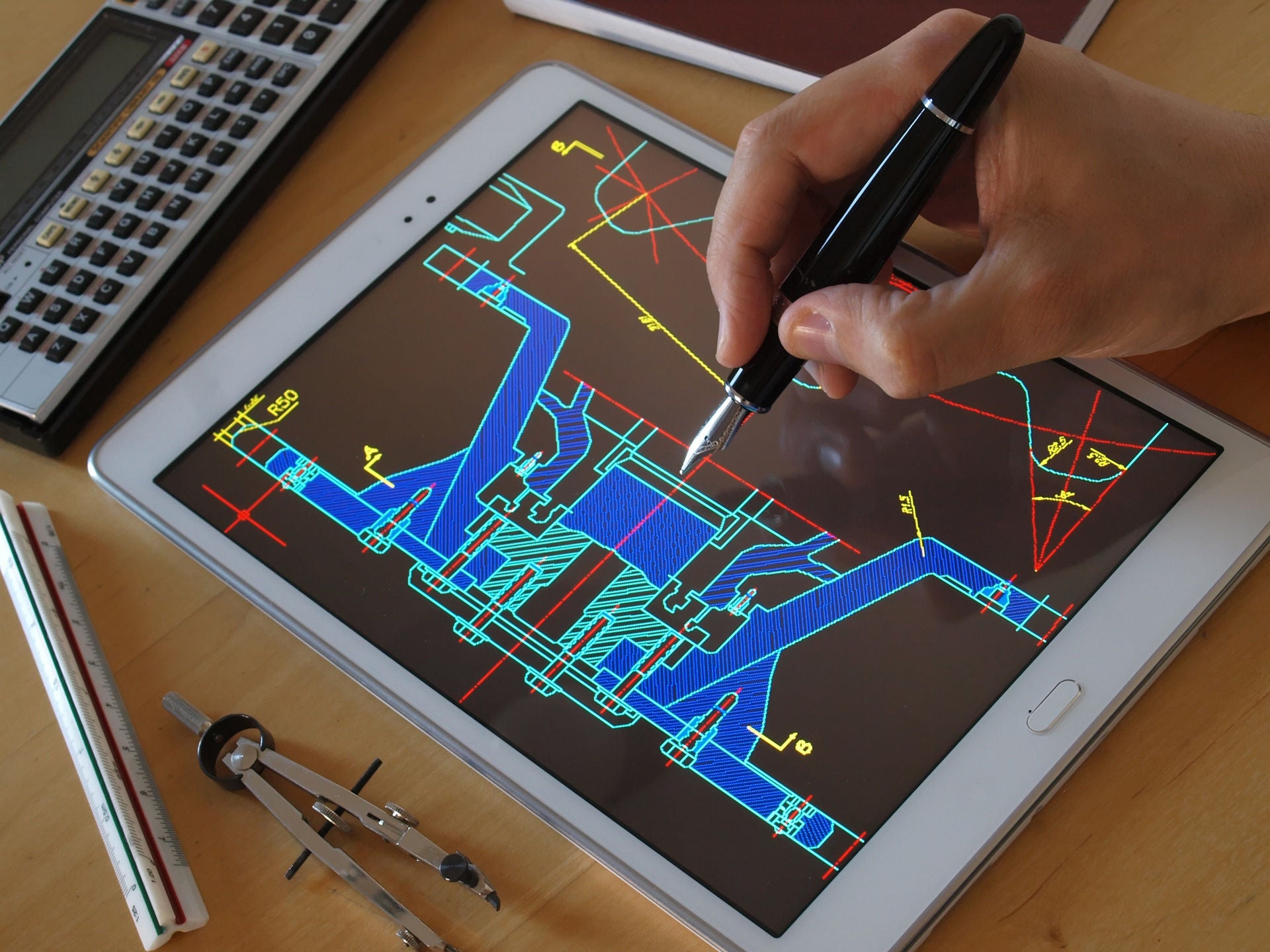

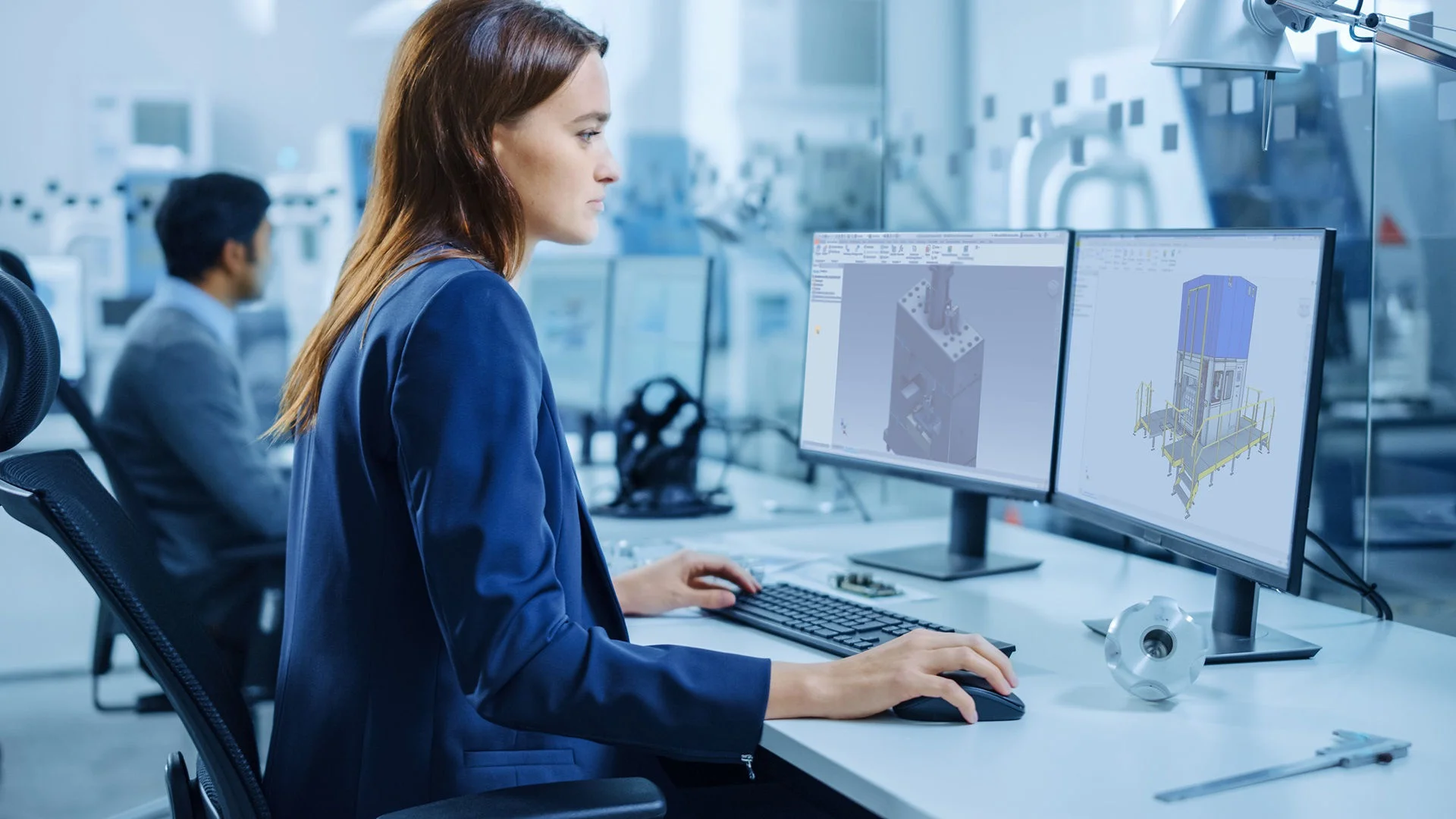

Cideon supports companies in machine building and plant construction with consulting for efficient software handling as well as solutions for end-to-end data integrity and information platforms along the entire value chain. This includes, for example, our interfaces, individual software developments, CAD software as well as PDM and PLM solutions.