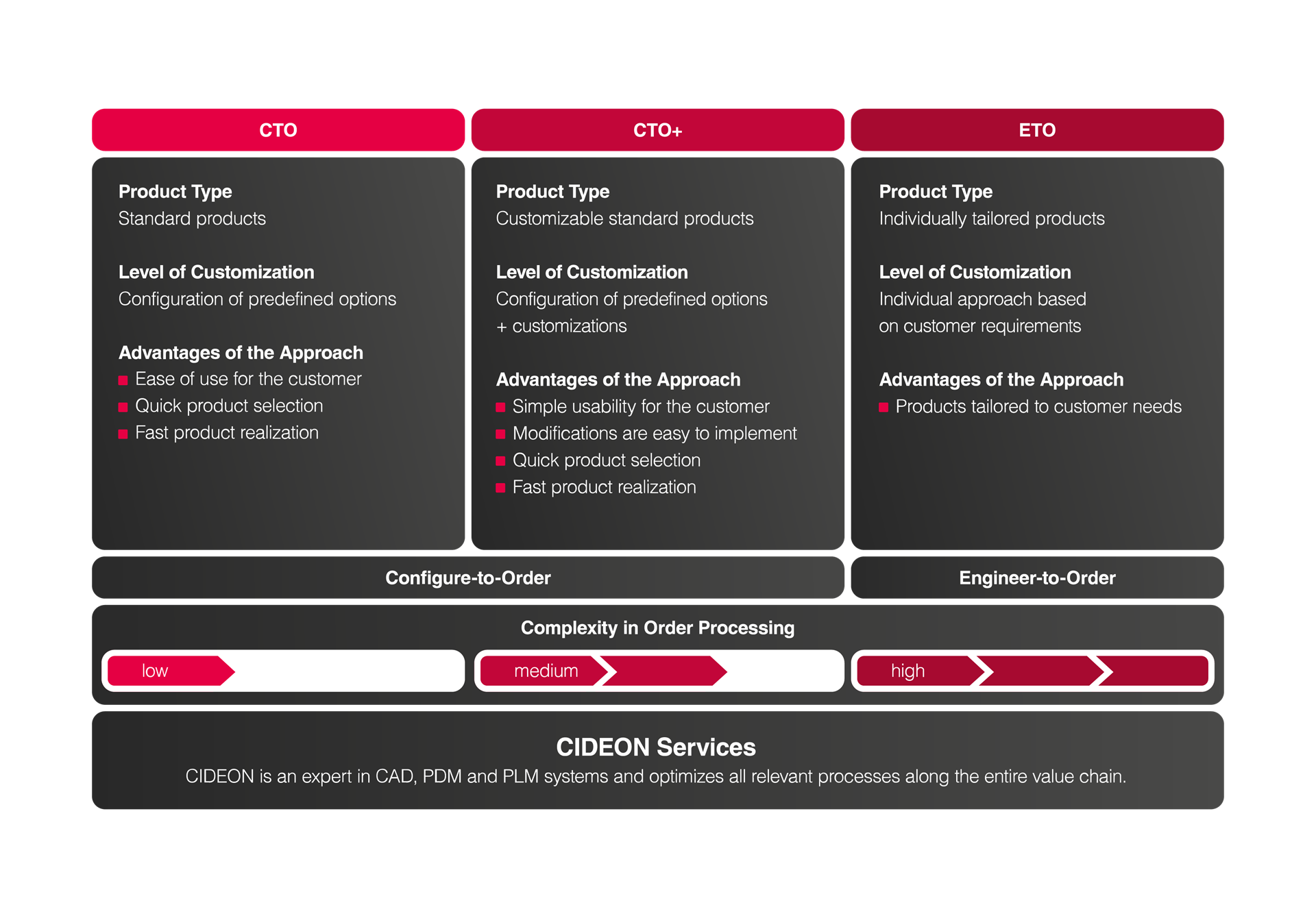

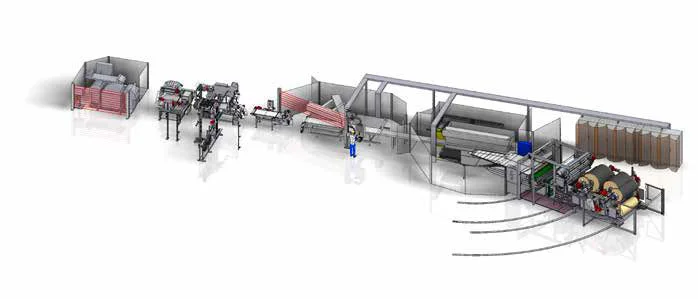

By modularizing and structuring the product portfolio, modules can be developed whose combinations lead to different variants of the product. This firmly defined combinatorics and the associated variants can then be displayed in a defined product catalog, for example. This alignment of the product is called Configure-to-Order. This approach differs from Engineer-to-Order (ETO), in which a fully customized solution is developed.

Traditionally, companies from the machine building and plant construction industries in particular have been strongly influenced by the ETO method and strive for a higher proportion of CTO.

With the CTO method, you can configure your product according to your individual needs by selecting from predefined options. Instead of developing your product based on a specific order, you can configure it with all possible components or options.

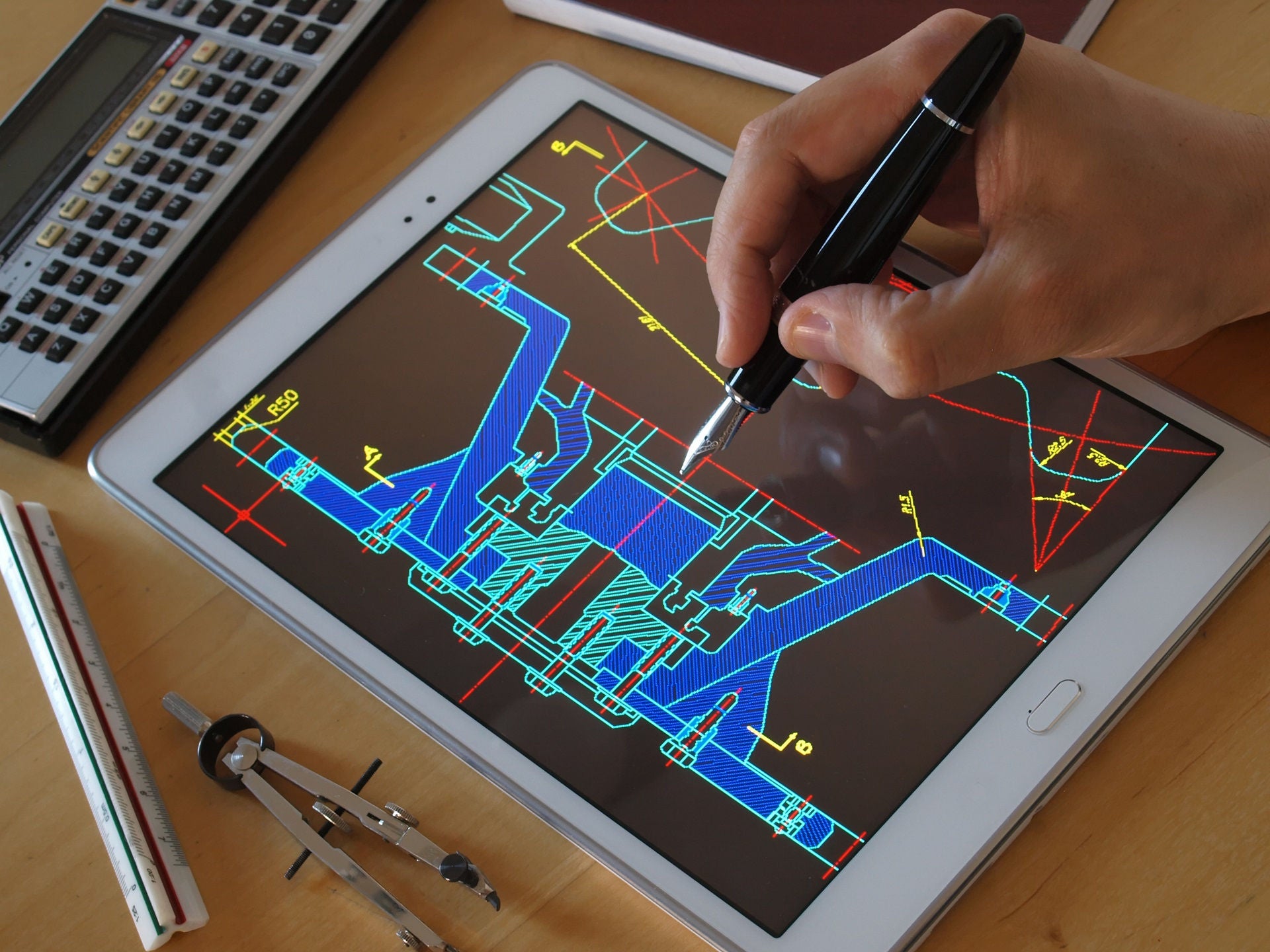

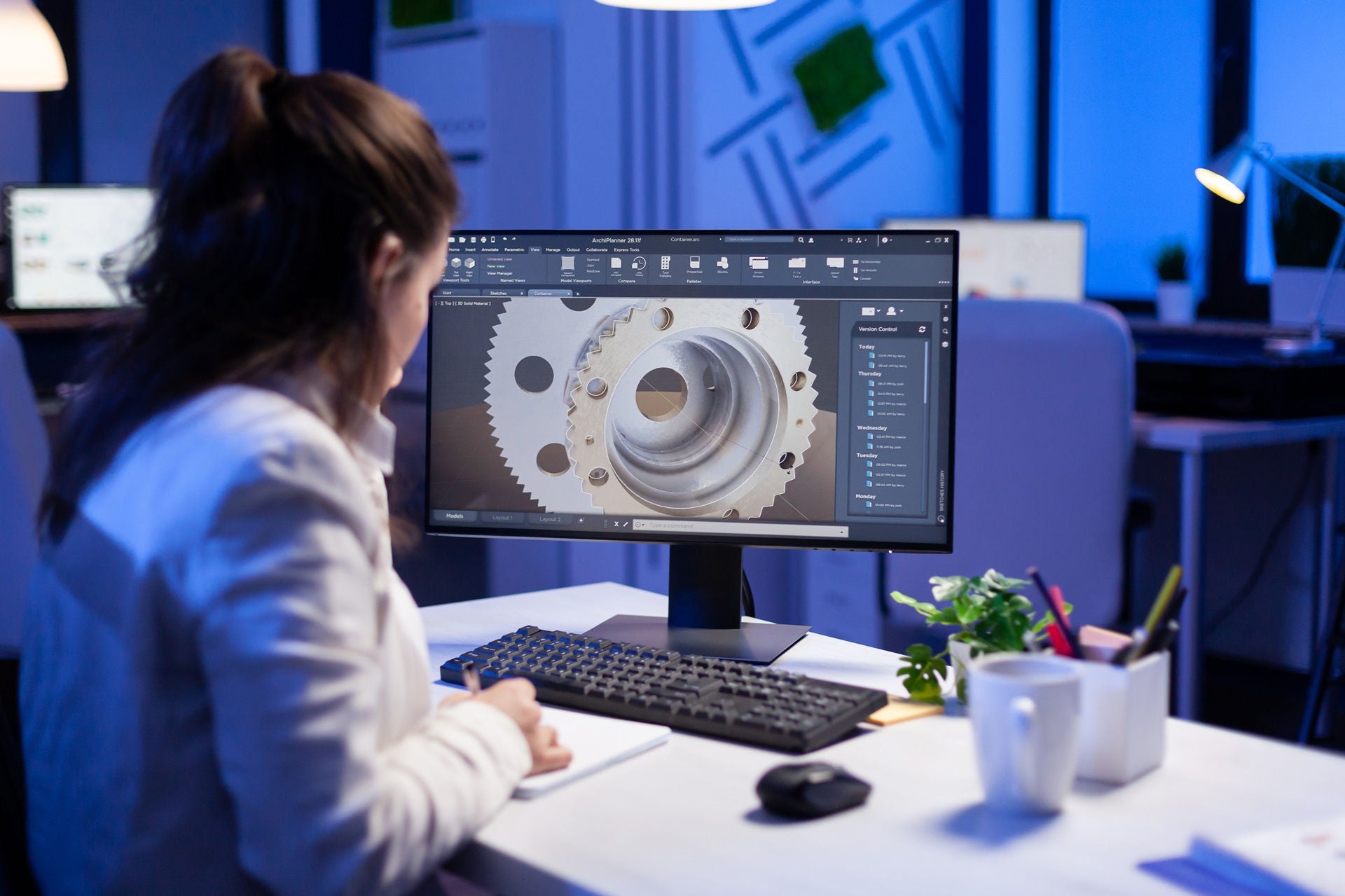

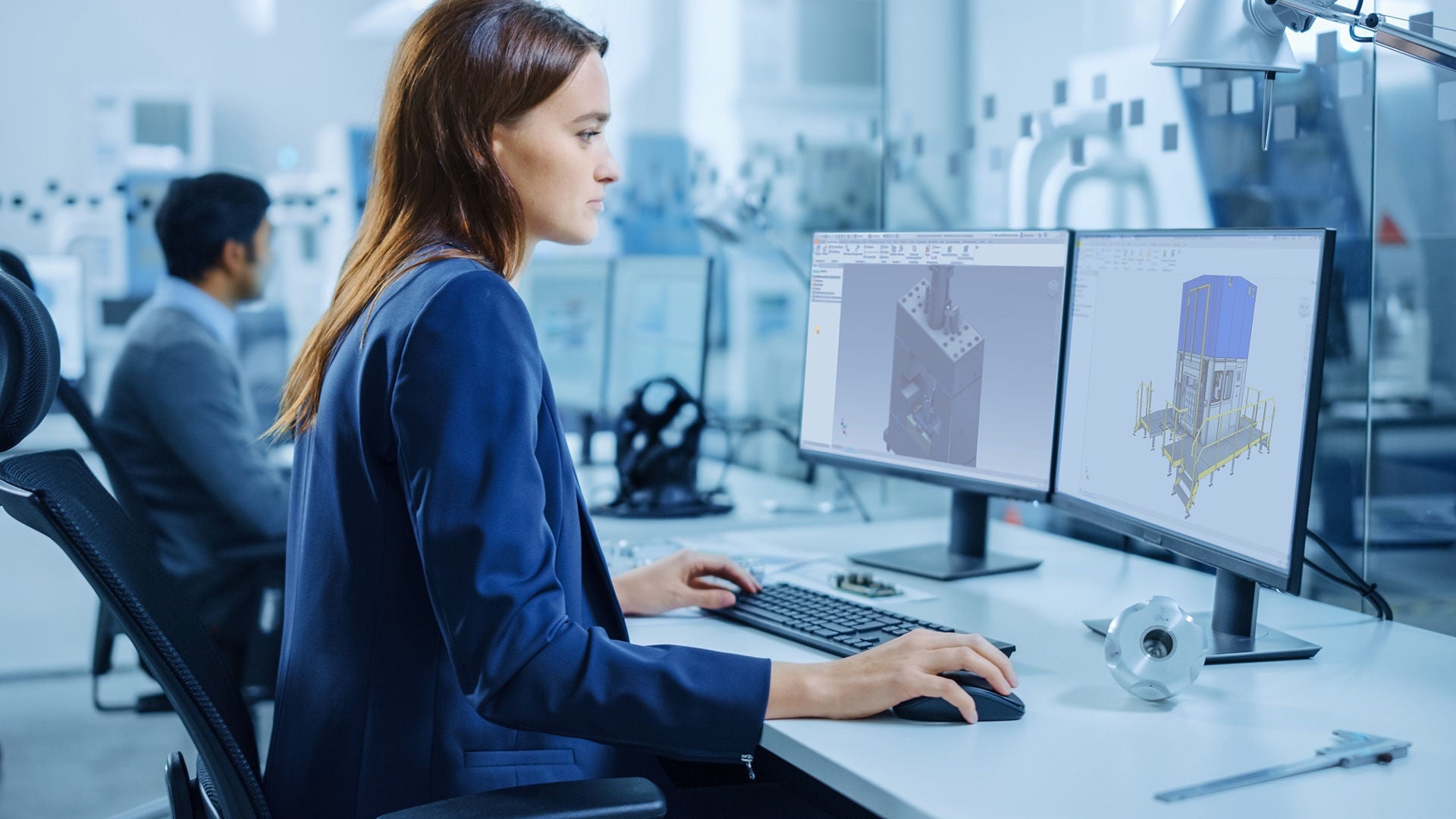

In terms of products, further standardization levels in CAD processing, known as engineering automation, promise further increases in efficiency in the CTO environment. In terms of processes, the concept of the smart factory will make it possible to mass-produce customized orders in the future. The digitalization of design and production is becoming a major catalyst here.

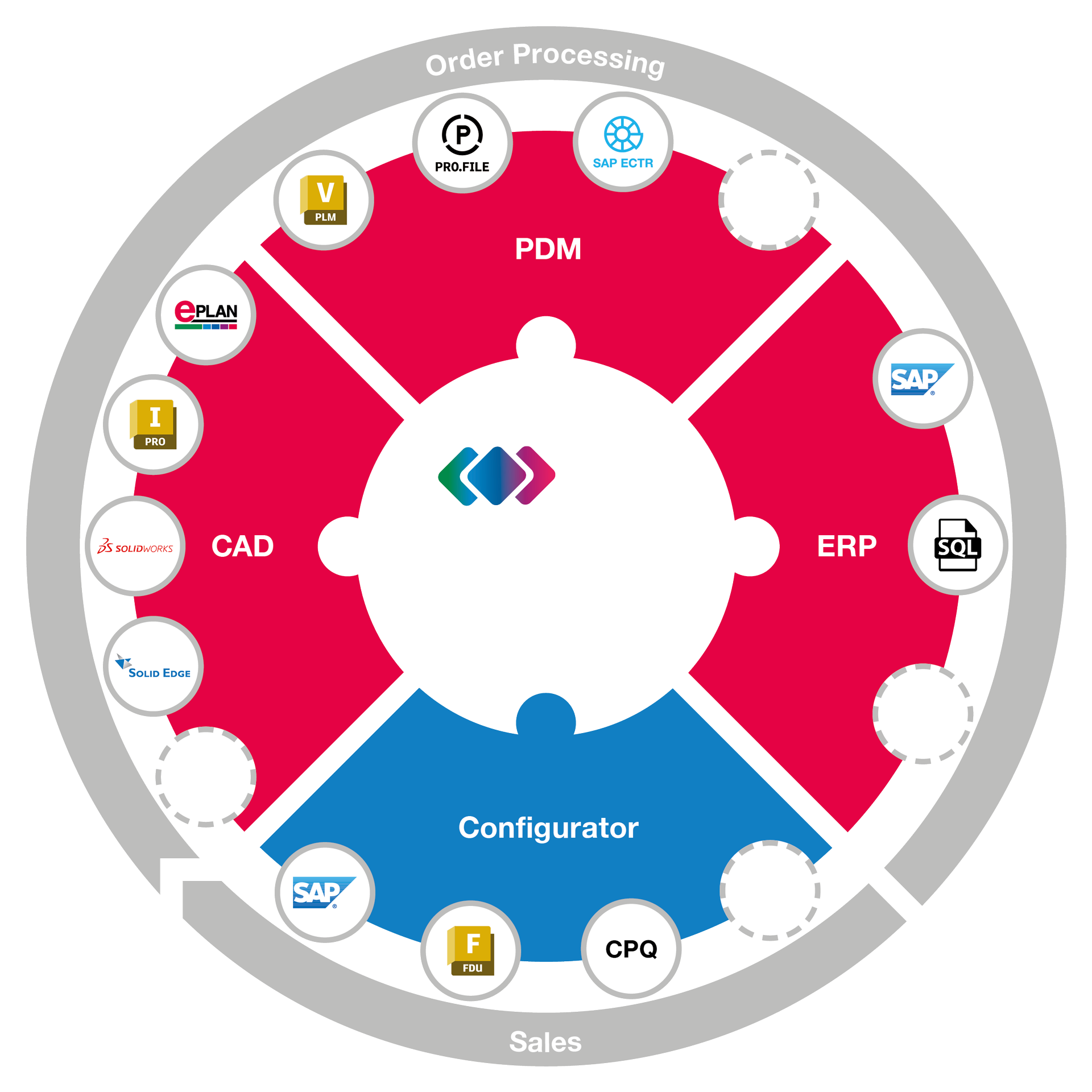

Cideon helps you to find, customize and implement solutions for end-to-end data integrity and information platforms along the entire value chain. Our Cideon Conify solution in particular is perfect for optimizing your configuration process and integrating all systems (CAD, PDM, ERP) into the process.