Powerful software is not enough to solve design challenges. You also need to get the most out of your CAD capabilities to meet the challenges of your day-to-day business. Do you know these situations?

Create a New CAD Standard with Uniform Design Guidelines

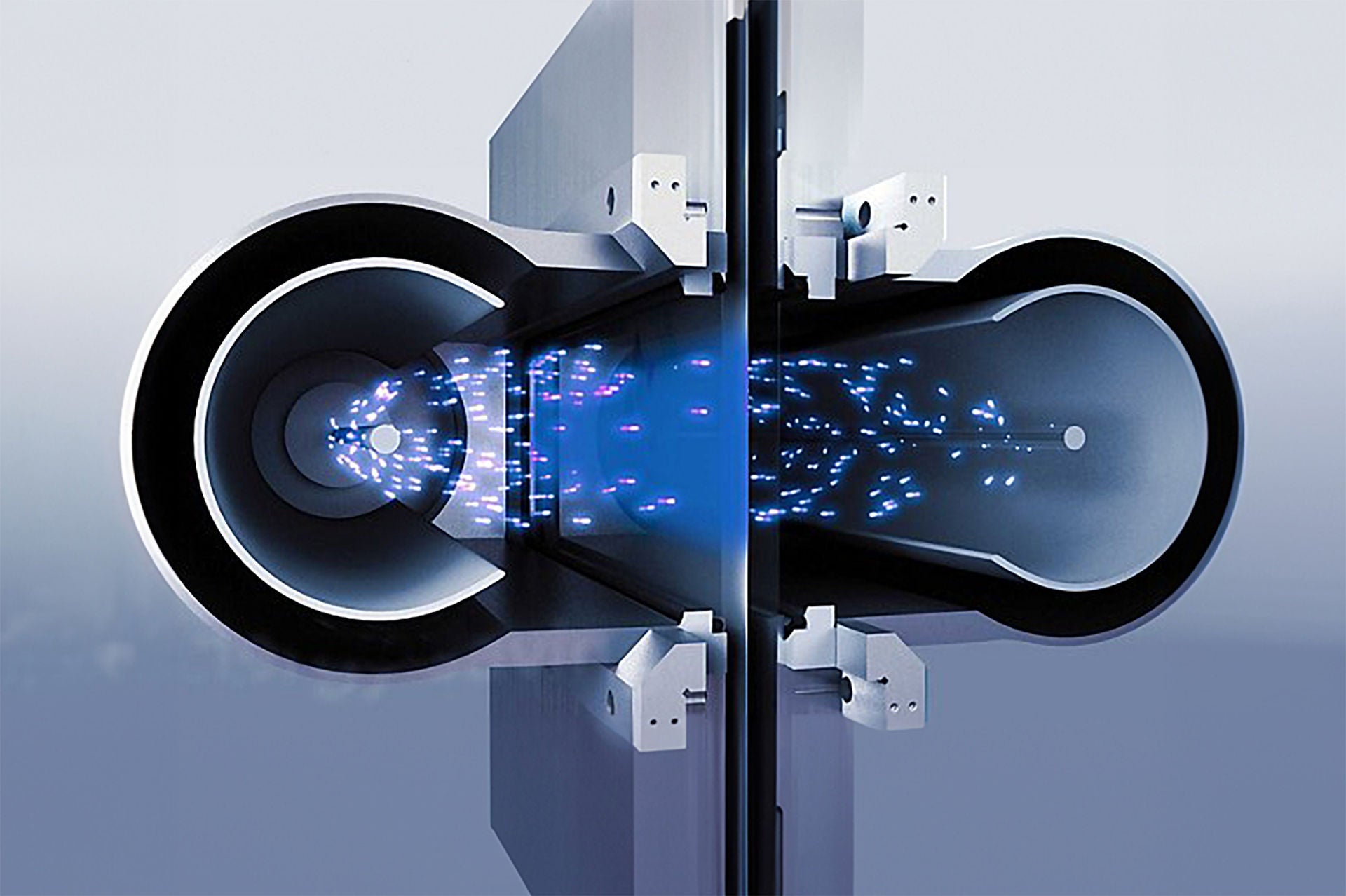

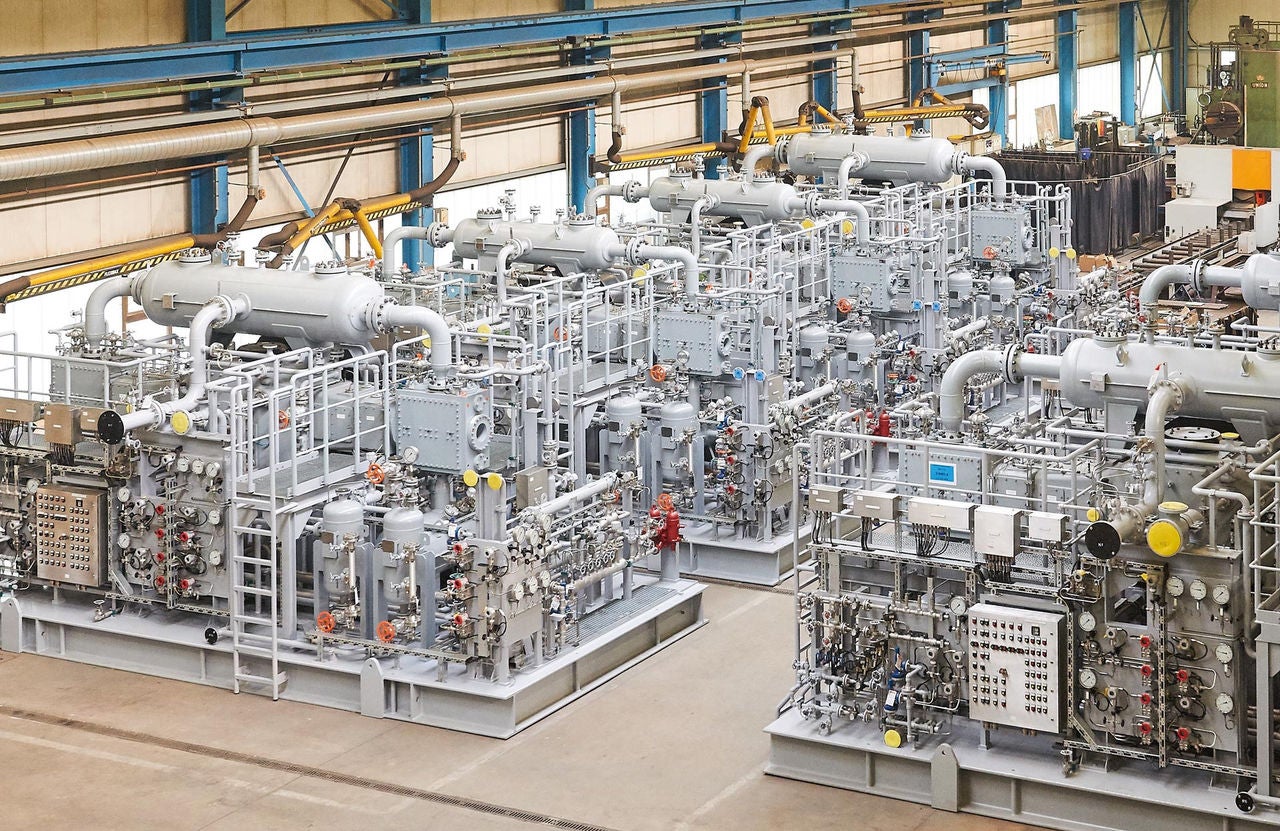

CAD Experience means that you fully utilize the available functions and tools of your CAD system to achieve more effective and higher quality results. You create change stability to ensure the integrity of your models, as well as traceability to document the steps of the creation process and optimize the collaboration of all parties involved. The basis for this is an adapted design methodology in the CAD system, high-performance assemblies and effective part reuse. Further building blocks can be calculations and simulations that ensure greater quality in design.

For both successful product development and subsequent order processing, it is crucial to master the software system with its diverse CAD functions. To achieve this, the possibilities of the system must be recognized and utilized. One key point here is the uniform design methodology with standardized components and parts as well as adapted standard and purchased parts libraries - including the necessary documentation. Tolerance analyses, checking 3D models for specifications and simulations are further, but not exhaustive, aspects of your CAD experience.

CAD automation is another important area that complements and optimizes your CAD experience. Automation tools and scripts can be used to automate repetitive tasks, which not only saves time, but also reduces errors and improves the consistency of your design processes.

Put your trust in our many years of experience in the CAD sector and let us advise you. We will be happy to help you develop and implement effective and practical design guidelines that will be used as the new CAD standard throughout your company.

CAD Design Challenges

What Contributes to an Optimal CAD Experience?

The following areas contribute to optimal engineering work.

Benefits of CAD Experience

There are good reasons why you should rely on CAD Experience! Discover them here:

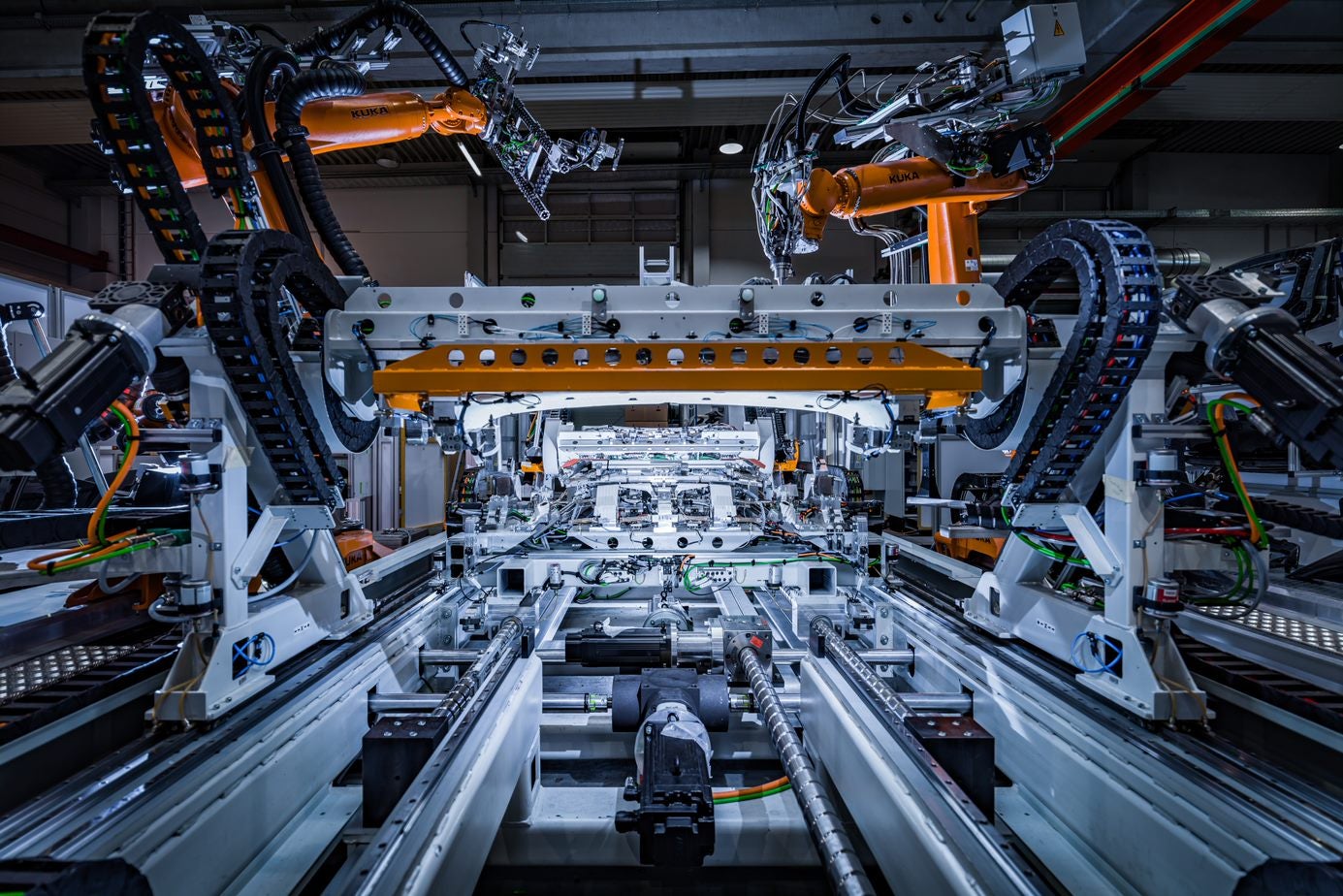

Engineering Automation

Design individual product variants fully automatically with Engineering Automation. As a software service package, Engineering Automation combines simple user guidance with the right engineering tool to create an automated solution. Discover different approaches and solutions to support you in the digitalization of your product development.

FAQ about CAD Experience

CAD Experience is a comprehensive solution for maximizing productivity in the CAD system. It supports engineers in exploiting the full potential of their CAD system, creating change stability and ensuring traceability throughout the entire design process.

The use of standardized design methods by CAD Experience ensures high-quality, reusable CAD data. This promotes the efficiency of the engineering department and increases the overall quality of the design.

CAD Experience addresses challenges such as time and budget pressure, faulty designs, ambiguities in the configuration process and the extensive training of new employees in various projects.

CAD Experience provides effective solutions to these challenges by making design more efficient, minimizing errors, optimizing production, improving quality and facilitating training and collaboration.

CAD Experience offers numerous advantages, including efficient design through defined standards and design methods, error minimization through automatic checking of design guidelines, production optimization through standardization of CAD data, increased quality and easier training and collaboration within the design team.

By using CAD Experience, the entire process is optimized, resulting in considerable time savings. This includes the elimination of time-consuming model checks, error minimization, more efficient production and faster training of new team members.

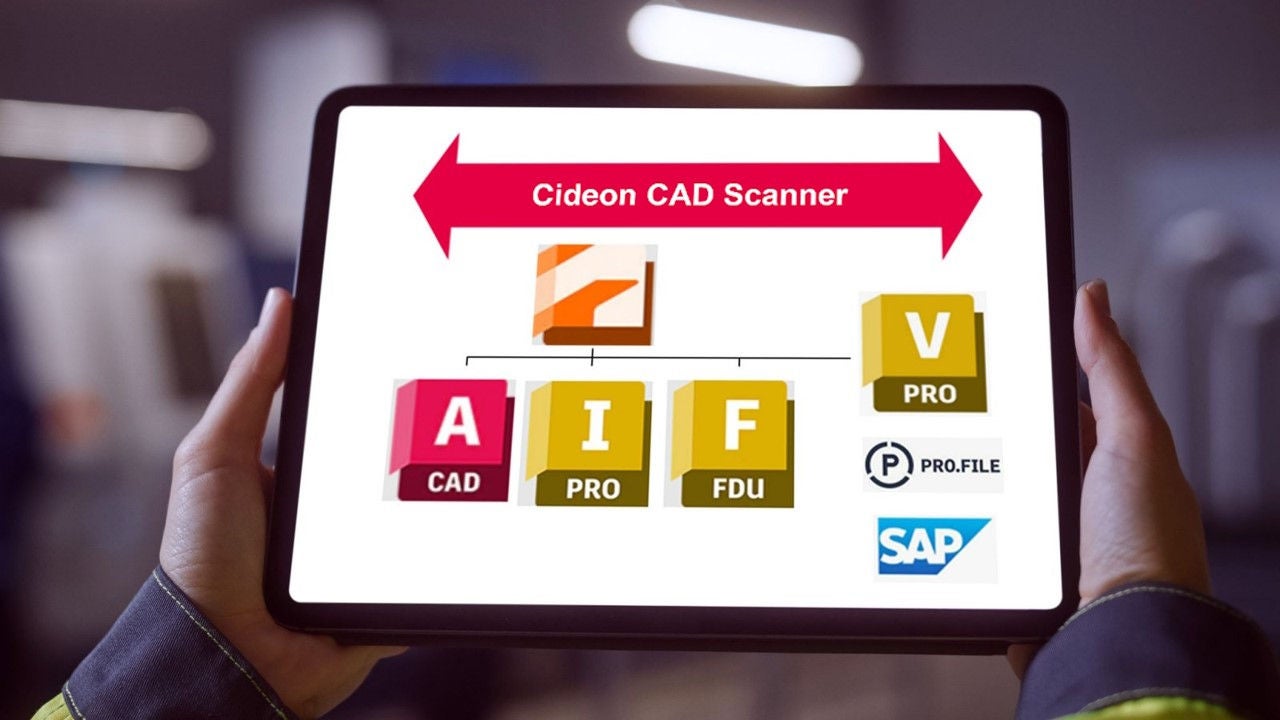

With Engineering Automation, you can design individual product variants automatically and thus accelerate your processes along the entire value chain. By automating your engineering processes at an early stage, you minimize your expenses in sales and after sales.

At the "push of a button", you can scale your designs in quotation and order creation. The starting point is Autodesk Inventor to create parameterized components as well as standard components and part families. In the next expansion stage, Inventor iLogic generates rule-based component, assembly and drawing documents. The highest productivity gains are generated by the subsequent use of further sophisticated automation tools.

CAD automation uses software to make design processes more efficient and error-free. In machine building and plant construction, routine tasks are accelerated by automated rules, which saves time, reduces errors, and increases productivity. Creative tasks are once again becoming the focus. This allows complex projects to be implemented more quickly and cost-effectively—a clear competitive advantage.

Why Cideon?

Cideon empowers companies to streamline product development – from initial concept to production and service. Our promise: measurable value through smart engineering and digital transformation.

Cideon Event Overview

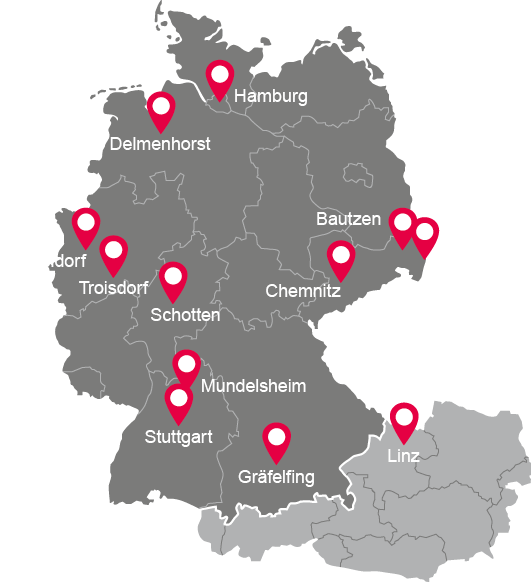

Cideon Locations

Cideon Headquarter

CIDEON Software & Services GmbH & Co. KG

Lochhamer Schlag 11, 82166 Gräfelfing (Germany)

Other Locations