Tetra Pak has a purpose to make food safe and available, everywhere. The company pioneered aseptic technology, which allows food and beverage manufacturers to package a commercially sterile food product so that it can last longer, be distributed further and stored without the need for refrigeration or preservatives. For many consumers, Tetra Pak is synonymous with beverage cartons, owing to the company’s heritage and innovation in the industry.

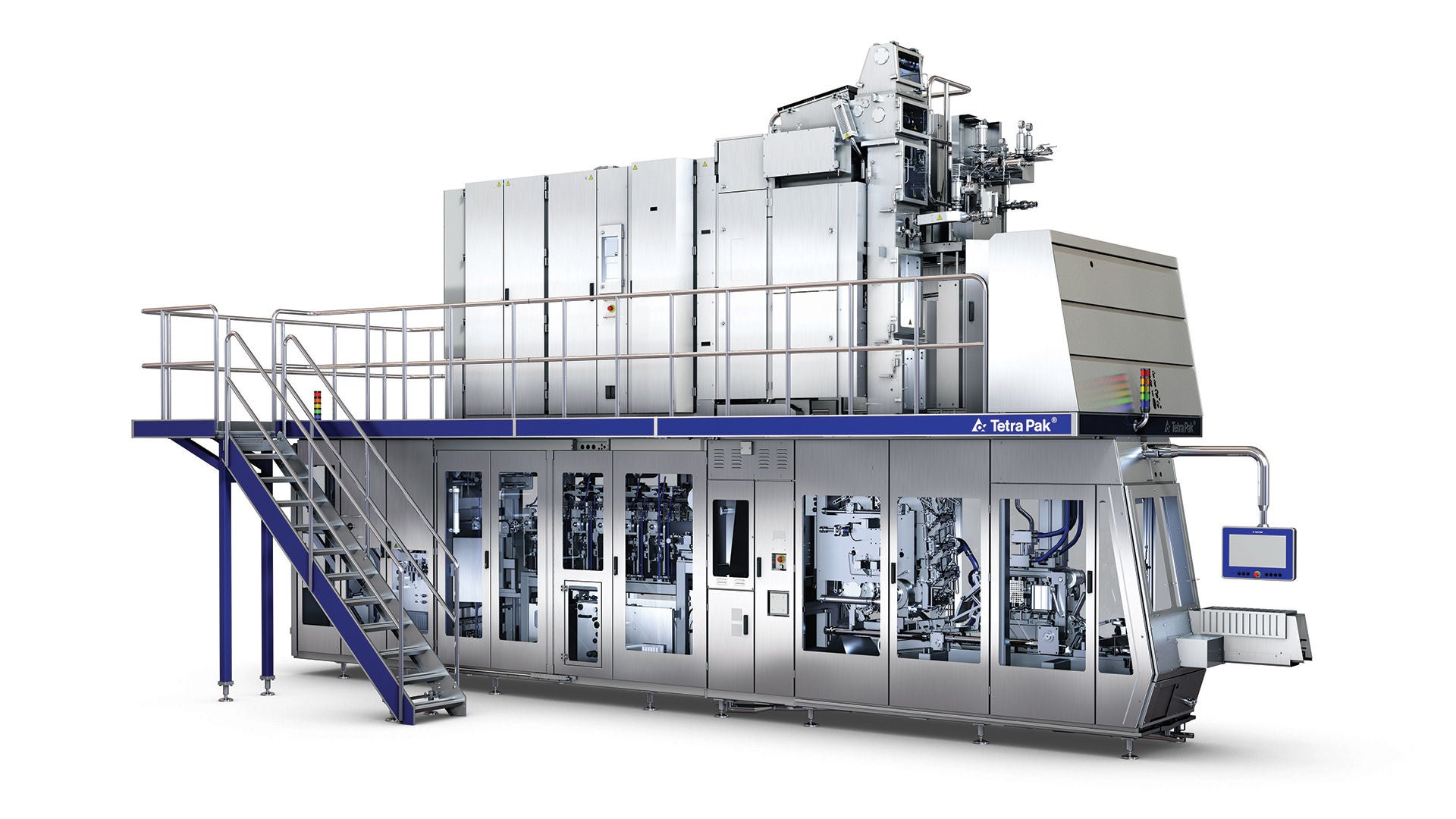

The company has developed into an international market leader for the processing and packaging of food. In order to ensure highest quality and hygienic standards, Tetra Pak produces the multi-layer packaging material and also the machines for the production and filling of food and beverage products.

From Chemical to Physical Packaging Sterilization

A crucial step in the filling process is the sterilization of the packaging material. Here, Tetra Pak can make a unique offer. Instead of chemical sterilization with gaseous H2O2, it´s just a low-voltage electronic beam that does the job. This has several advantages: No chemistry is needed, less waste is generated, the “eBeam” modules are very compact, and the user can run the machines up to 60% faster – with, for sure, the same hygienic quality.

The eBeam modules have been developed and are produced in Flamatt/Switzerland. For the design of the modules, the eBeam team used a customized SOLIDWORKS system which sent its data to SAP ECC, using SAP´s CAD Desktop integration tool. Now, a standardized SOLIDWORKS PDM Professional solution with a connection to SAP S/4HANA Public Cloud should be implemented.

The Missing Link: Connection Between CAD/PLM

When the PDM system with all its engineering and product data is deeply integrated into the (cloud-based) enterprise resource planning (ERP) system, there is a consistent data stream and a “single source of truth” for the combination of engineering data (CAD) and commercial/product data used, for example, for purchasing and production planning.

Sven Muregard, project manager for this project at Tetra Pak: “The engineers were satisfied with SOLIDWORKS. So, we took the next step with SOLIDWORKS PDM Professional. And, as the appropriate SAP solution, we opted for S/4HANA Public Cloud because it is the most standard

The Solution: New Cideon Connector

This idea seems simple – but to link these two systems or worlds, a separate connector is needed. Exactly this interface – ensuring the SOLIDWORKS PDM integration to SAP S/4HANA in a Public Cloud environment – had just been developed by Cideon. So, Tetra Pak opted to use this new connector.

The decision was facilitated by the fact that both companies already collaborated in the CAD area. Sven Muregard: “The eBeam users were happy with the SAP CAD Desktop solution from Cideon. We had a very integrated process of engineering and resource planning, and our intention was, of course, to continue to work that way.”

Read more about the project between Tetra Pak eBeam Systems and Cideon in the reference report:

How do you become a Cideon reference customer?

Are you currently working successfully with us on a joint project? Each of our customers is individual, has specific requirements and therefore very different solutions that are implemented. For us, every customer project is unique and should be valued just as much.

In our reference reports we focus on your company, the project highlights and your benefits.

Would you like to present your company and the joint project even more prominently? Then simply contact your responsible Cideon Account Manager and we will take care of all the further details for creating a reference report and publishing it on our website, blog and social media.