Principle: The Customer is King

If you compare the three-man start-up in the 80s with today's world-renowned medium-sized company, you will quickly realize that it is not mass production that has made Teledoor successful. It was - and still is - the claim of the classic variant manufacturer to deliver the right solution for every customer with excellent workmanship and to never say 'no' to any customer.

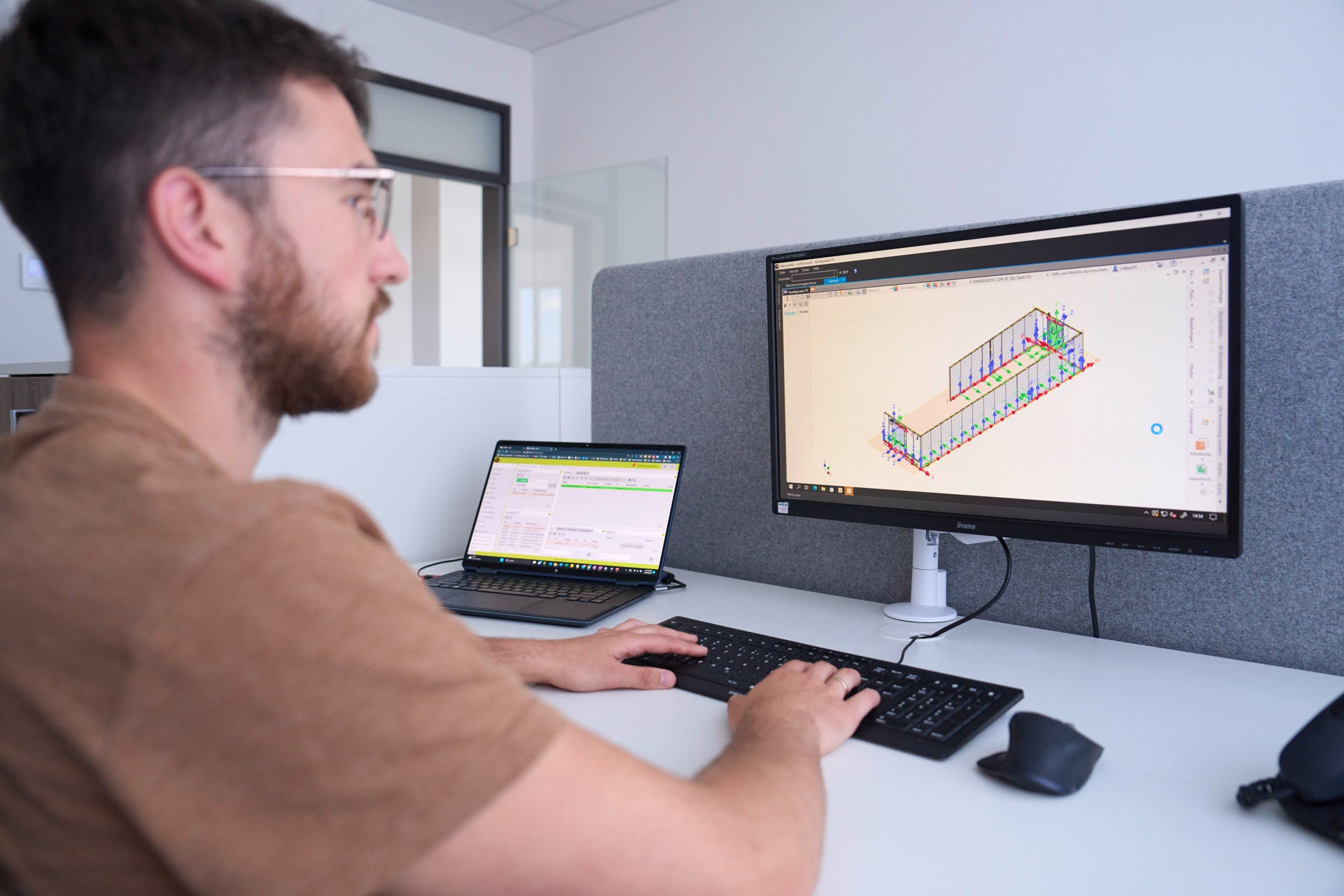

Those who, like Teledoor, do not compromise on customer orientation in the slightest can run into problems with classic engineering-to-order: in terms of margins, competitiveness and also within the team, as complex tasks also mean effort. This increases with the number of orders increases, which led Teledoor to look for efficiency potential. The company realized that the engineering department, with its 27 CAD workstations, was increasingly becoming a bottleneck and could no longer keep production running at full capacity.

Focus on Pain Points

The potential analysis identified three main weaknesses: CAD, processes and strategy. Initially, the engineering department was lagging behind the incoming orders because too much repetitive work meant a very high and error-prone time investment.

Daniel Krämer, Head of IT & Digitalization at Teledoor: "In the end, our colleagues had to repeatedly assemble the same things in different dimensions. Only the smallest part of their work consisted of their actual task: design".

Another area where the cost/benefit ratio was disproportionate was the spare parts business, because it had to be permanently approved by the engineering department so that the standard interfaces to the ERP could be addressed. "In addition," explains Daniel Krämer, "we had to take action because we were unnecessarily inflating our database: Many components were identical but had multiple part numbers because they had been copied into the PDM system. Ultimately, there was a lack of overview and a clear approach, as certain standards get lost in an engineering department with more than 20 people."

The real endurance test, however, was the communication between the departments, for example in the case of last-minute order changes. Krämer adds: "These can end in complete chaos if data redundancies occur, for example from the creation of the order in text form, through its implementation in a CAD design, to the information for production."

Three Steps to Configure-to-Order

The road to Configure-to-Order was not an easy one, but it was a logical one. Teledoor divided the project into three stages. First, the master elements were entered into CAD, then the actual CAD automation via iLogic, and finally the transfer of the engineering documents.

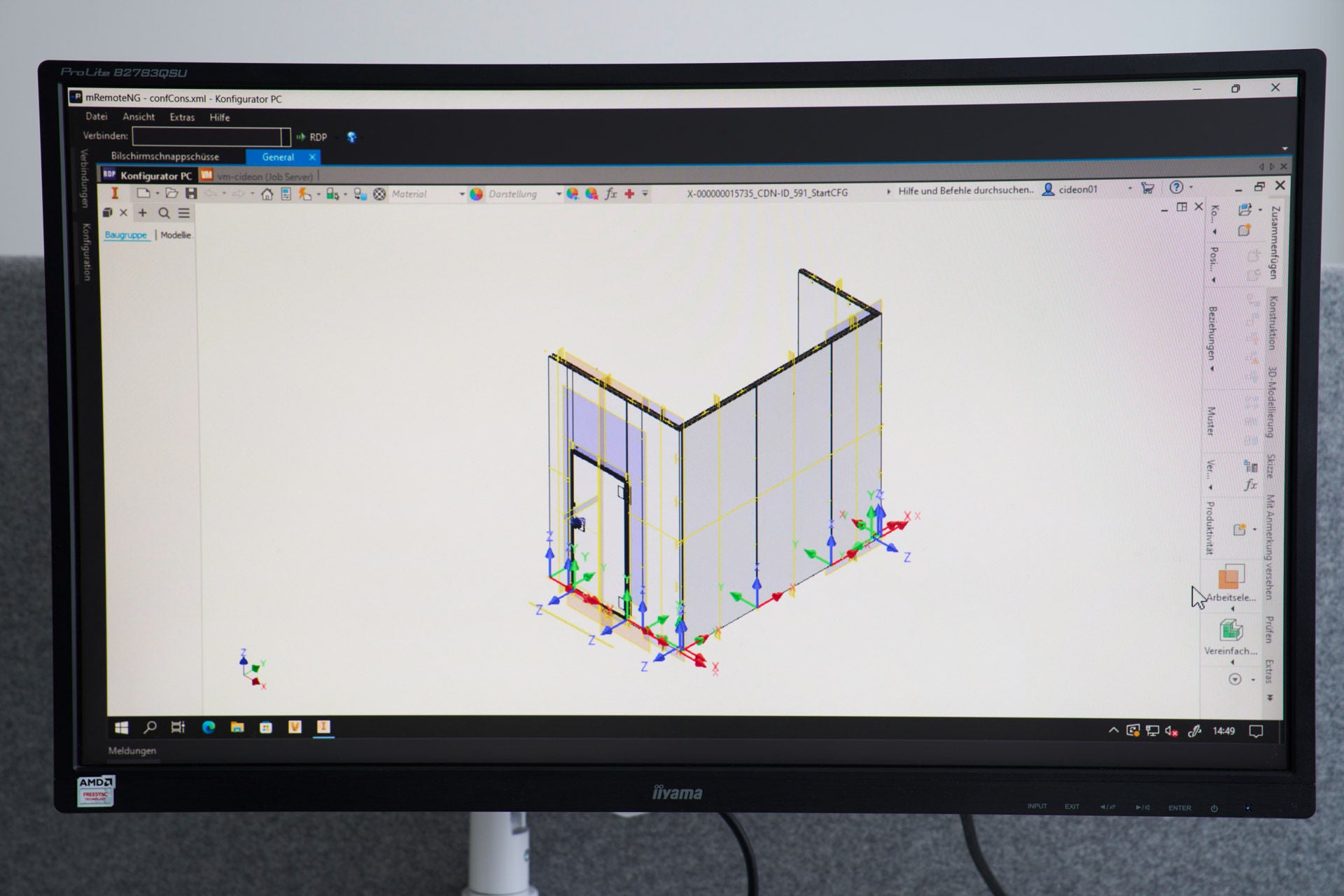

In iLogic, a tool for standardizing and automating engineering processes and configuring virtual products, the engineering principles were integrated as objects directly into component, assembly and design documents. Teledoor provided a trained team of four, ranging from university graduates to experienced engineers.

In collaboration with Cideon, Teledoor then created the configurator cockpit for the company's sales staff - "a nice graphical interface that simplifies the whole thing and keeps the application easy to use. We are now in the process of setting up our own department for the expansion and operation of the configurator, in order to further develop the features and specifications and to be able to meet all requirements," says Krämer.

This department is currently also working on setting up additional configurators for other product lines such as refrigerated doors, discount stores and the spare parts business. Krämer: "In the final stage, we want to cover 60% to 70% of all orders via the no-touch process, with 30% to 40% going to the engineering department." The manual engineering effort will definitely remain, although it will be minimized by a hybrid engineering method called "No Touch Plus".

Teledoor’s engineers are supposed to use the configurator to achieve a 70 percent approximation, and then design the remaining 30 percent – which is usually much more complicated to realize - themselves.

Read more about the project between Teledoor and Cideon in the reference report:

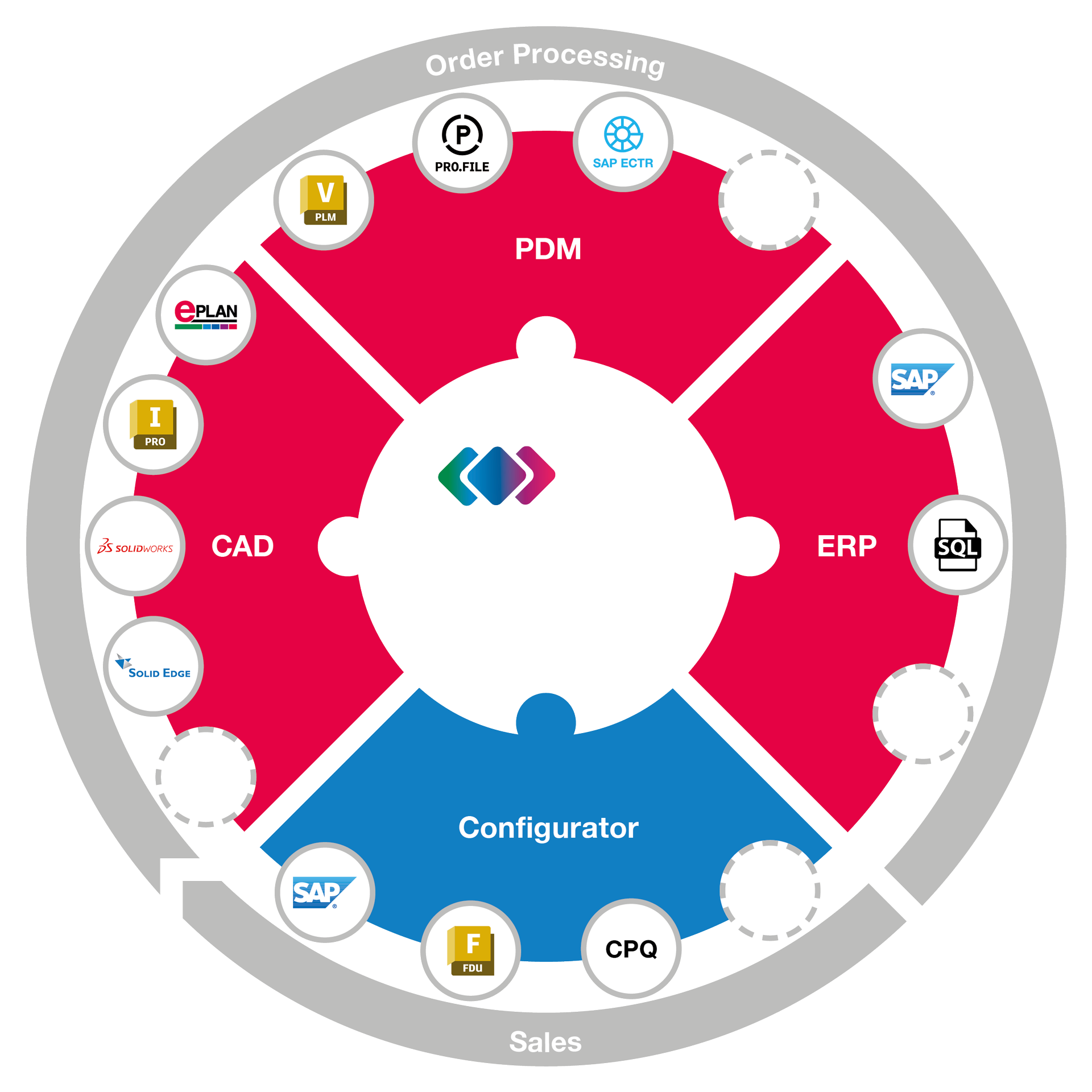

Cideon Conify

Software Solution for a Consistent Configuration Process

Cideon Conify consistently links data from the sales and engineering phases to automatically provide PDM-compliant MCAD and ECAD data of the configured product. This is the basis for the subsequent engineering-to-order and the creation of ERP-specific parts lists, work plans, circuit diagrams and production processes according to customer requirements, so that individual products can be created quickly and in accordance with specifications.

Main advantages:

- Automate daily tasks when processing configurable products

- Consistent data quality

- Ensure uniform standards for everyone involved in the process

- Combination in a mechatronic parts list

Cideon Conify is the ideal combination of CONnection and CONfiguration!

How do you become a Cideon reference customer?

Are you currently working successfully with us on a joint project? Each of our customers is individual, has specific requirements and therefore very different solutions that are implemented. For us, every customer project is unique and should be valued just as much.

In our reference reports we focus on your company, the project highlights and your benefits.

Would you like to present your company and the joint project even more prominently? Then simply contact your responsible Cideon Account Manager and we will take care of all the further details for creating a reference report and publishing it on our website, blog and social media.