Integrated SAP ERP/PLM system for shorter processing times in plant engineering

Innovation has a very long tradition at NEA. The beginnings of the family-run company based near Aachen, Germany, date back more than 180 years to the time of the (first) industrial revolution. NEA is now a global group of companies with around 1,000 employees whose core expertise include the manufacturing of compressors for air and technical gases. NEA are able to produce innovative products in the shortest possible time due to their skilled employees and an innovation-friendly corporate culture. “We specialize in delivering exceptional applications so we need to keep one step ahead of the current state of technology,” stresses Karl-Josef Kremers, head of plant engineering at NEA Germany.

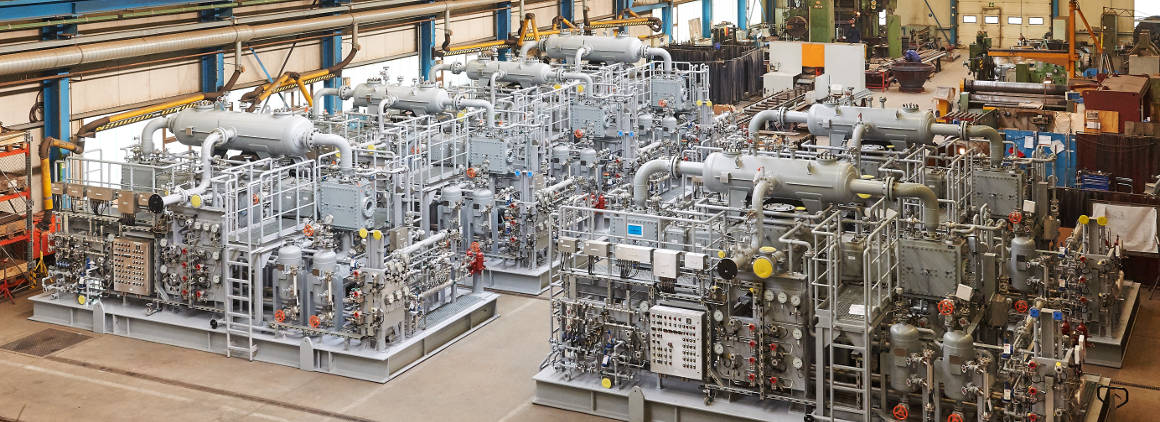

NEA Compressor Technology (CT), which employs around 270 people in plant engineering, has six engineering locations in six countries worldwide. Their task is to plan and design the system technology around piston compressors, to procure accessories and to supply customers with turnkey systems for their processing needs. “Engineering is always carried out under the supervision of the local NEA company. This benefits our customers because purchased parts such as coolers, engines, filters, etc. comply with local standards and are known and available locally,” says Kremers.

Standardizing the IT landscape

Like other plant and system engineers, NEA faces the challenge of developing customized systems within short deadlines. Synergy effects are gained through a constant sharing of knowledge between the sites, so at NEA, the wheel requires inventing only once. NEA reduces engineering effort by partially standardizing specific product components and globally standardizing tools, methods and processes.

“Standardizing and networking the IT landscape is the key,” stresses Kremers. “On the one hand, we want to share information and expertise at the sites independently of specific customer projects. On the other hand, we also want the experience and capabilities of the individual sites to be available for cross-location projects”. As part of standardizing the IT landscape, NEA replaced an older ERP system which, despite being state-of-the-art, was no longer able to meet the growing demands of the corporate structure. SAP ERP was then implemented. With SAP software as a basis, the company also implemented, with support from Cideon, the integrated SAP PLM solution which manages CAD data and documents throughout the process. The aim of the integration is to interlink technical and logistical business processes more closely and shorten order processing times.

The “single source of truth” approach also means the company will benefit from a higher reusability level of existing drawings and documents when planning and budgeting new projects. In addition to replacing the ERP system, a new CAD software solution was sought for the worldwide engineering locations because the existing system’s provider intended to discontinue support in Europe.

After detailed evaluation of the plant engineering CAD systems avail-able on the market, the Autodesk Plant Design Suite was chosen because it best met requirements. Mike Gorgas, project manager responsible for the introduction of SAP PLM said the key criteria were comprehensive 2D/3D functionality, the provider needed to be a global operator, the cost-benefit prognosis was good as well as integration options to the SAP world. “The specific benefits of integrating CAD and SAP only became apparent to us after implementing projects with Cideon,” adds Kremers.